Proven Results

In Demanding Applications

Proven success for over 18 years

One Eye Industries offers a series of products designed to help organizations achieve rapid payback with the lowest risk by extending the life of rotating equipment. Each filter is optimized for fluid viscosity, flow volume, flow rate, temperature, mobility, and mounting requirements. Use of the OEI Data Form will provide the necessary specifications for OEI to determine which product will provide optimal efficiency.

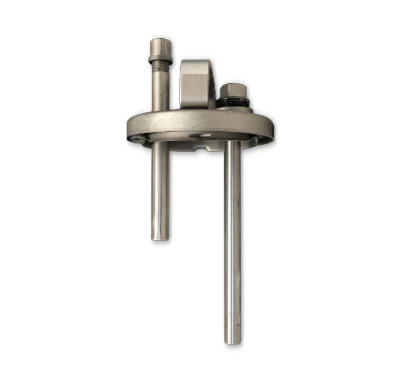

The patented magnetic filter element attracts ferrous wear particles down to 4 microns and below with up

to 95+% efficiency. The magnetic filter element attracts both ferrous and non-ferrous particles. The radial magnetic field design offers incredible holding strength and a high dirt holding capacity.

OEI magnetic filter elements are employed in various housings designed with calculated dwell times for optimal filtration. Magnetic filter elements come in five sizes from 1/2” to 2” OD.

CleanMud Magnetic Filtration Systems filter wear contamination from oil, water and chemical-based mud, along with fracking and completion fluid. The patented technology removes more than 95 per cent of wear contamination down to and below one micron in size.

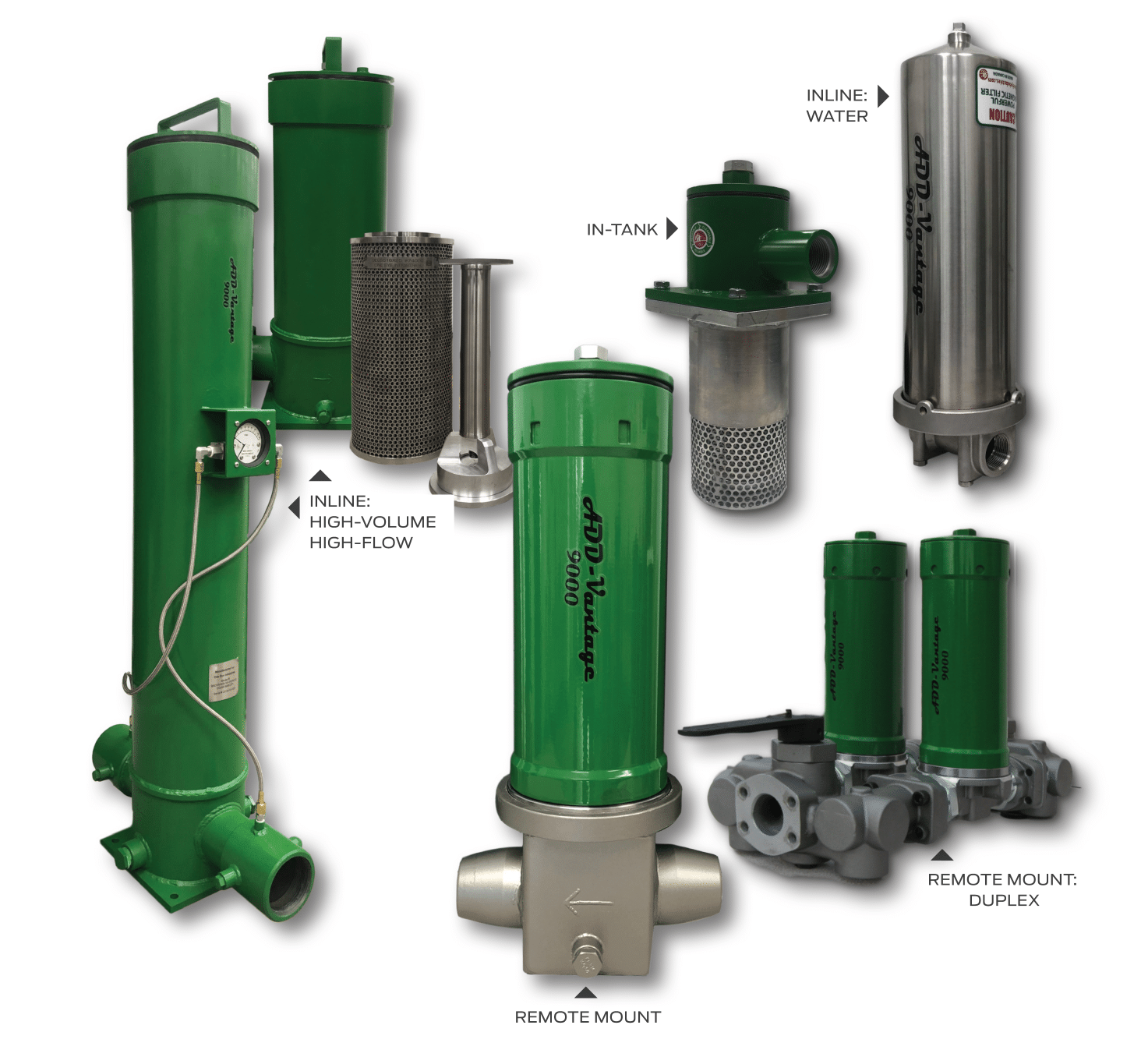

ADD-Vantage 9000 Series

The ADD-Vantage 9000 magnetic filtration system employs a magnetic element and a stainless steel cloth element in its design for high efficiency filtration and replaces conventional spin-on cartridge filters. Specialty designs include the ADD-Vantage 9000 High Flow and the ADD-Vantage 9000 Stainless Steel.

ADD-Vantage 9000

Standard

ADD-Vantage 9000

VS Series Stainless Steel

ADD-Vantage 9000

800 High Flow

Ultrasonic

Enviro-Wash Station

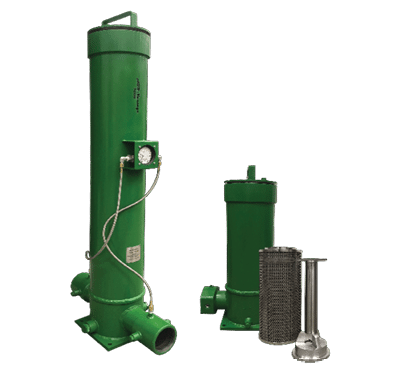

Magnetic Filter Scrubber Series

Magnetic filter scrubbers employ a magnetic filter element in a specialty housing designed to operate with minimal flow restriction and maximum fluid exposure for high-efficiency filtration. Flow is regulated by the diameter of the inlet-outlet supply pipe as well as fluid velocity. These systems install on suction and return lines of high-pressure and low-pressure applications.

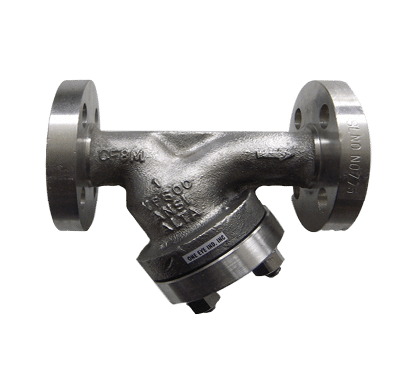

Magnetic Filter Y-Strainers

OEI Magnetic Y-Strainers are recommended for low-flow applications with space restrictions. This filter employs a magnetic filter element and mesh screen. Systems are designed for the application’s fluid, flow volume, viscosity, mobility, and mounting requirements. Y-strainer designs are offered for cryogenic, high-pressure, and high-temperature applications.

Magnetic Filter Plugs

OEI Magnetic Filter Plugs are the high quality replacement for OEM ceramic magnet drain plugs. Designed with the highest quality rare-earth magnets fastened to the plug body, the magnetic filter plug captures abrasive wear particles and prevents them from circulating throughout the system. OEI Magnetic Filter Plugs have a high holding capacity and they resist vibration and high-temperatures that typically reduce conventional strength over time. OEI Magnetic Filter Plugs are effective predictive maintenance tools when integrated into maintenance programs.

Magnetic Filter Pads

The Bear Trap Magnetic Filter Pads attach to existing disposable spin-on filters to trap the contamination (sludge) that wears on system components and causes equipment failure. Capturing the wear contamination under 4 microns will extend fluid life (extending fluid changeout intervals) and equipment life (extending maintenance intervals).

Magnetic Emergency Patch

OEI Magnetic Patches provide an immediate solution to pipe wear or rupture by magnetically adhering to surfaces and preventing leakage. This patch is a temporary solution to prevent unscheduled downtime during production.

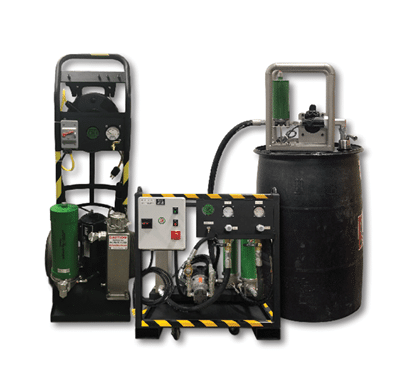

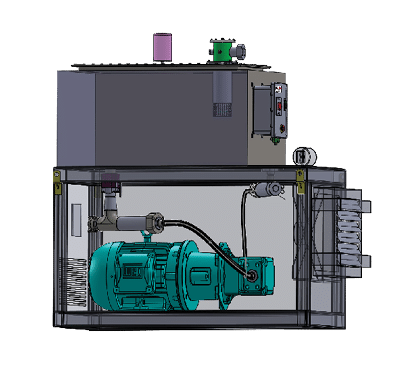

Kidney Loop Systems

OEI Kidney Loop Systems are self-contained filtration units for off-line filtration, fluid transfer of mobile or stationary equipment, and flushing of storage reservoirs. Systems are designed for fluid viscosity, temperature, mobility, and installation requirements.

Hydraulic Power Units (HPU)

3-Stage magnetic filtration for Hydraulic Power Units (HPU) ensures heavy-duty hydraulic equipment protection with minimal maintenance requirements. Cleaner fluids enhance the reliability of the HPU, optimizing it for remote, inaccessible work sites. The core technology, found in all One Eye Industries products, is a magnetic filter element with a patented radial field magnetic configuration that captures wear particles down to 4 microns or less, with up to 95+% efficiency.

Specialty Designs

OEI offers customers sustainable, higher-efficiency alternatives to OEM magnetic filters, as well as specialty designs that enhances filtration of critical fluids on OEM mobile equipment. OEI designs replacements for all major filter manufacturers like PALL, Parker, CAT, Komatsu, and Schroeder.

OEI also offers specialty designs for facility applications to support unique installation requirements.

Distributor Sales Kit

One Eye Industries Product Demonstration Kits are a valuable tool to customers and distributors wishing to demonstrate the capabilities of OEI technology. Each kit is compact, portable, and equipped with a sample of OEI’s core product lines. Kits include tools to showcase the comparison between OEM magnetic filtration and OEI’s patented magnetic technology.

Protect Your Equipment

Download The Ultimate Guide To Fluid Management And Equipment Reliability

4344 12th Street SE Calgary,

AB T2G 3H9 Canada

(403) 242 4221

quotes@oneeyeindustries.com