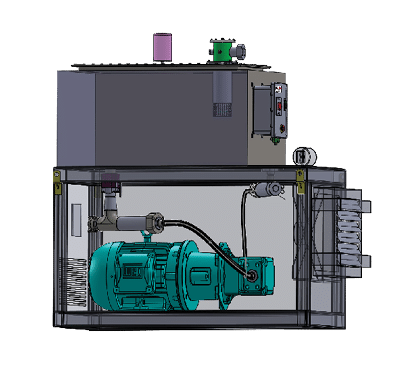

Hydraulic Power Units

3-Stage magnetic filtration for Hydraulic Power Units (HPUs) ensures heavy-duty hydraulic equipment protection with minimal maintenance requirements. Cleaner fluids enhance the reliability of the HPU, optimizing it for remote, inaccessible worksites. The core technology, found in all One Eye Industries products, is a magnetic filter element with a patented radial field magnetic configuration that captures wear particles down to 4 microns or less, with up to 95+% efficiency. The radial magnetic field design offers offers up to 10 times more holding capacity than traditional filters.

About

3-Stage magnetic filtration for Hydraulic Power Units (HPU) ensures heavy-duty hydraulic equipment protection with minimal maintenance requirements. Cleaner fluids enhance the reliability of the HPU, optimizing it for remote, inaccessible worksites. The core technology, found in all One Eye Industries products, is a magnetic filter element with a patented radial field magnetic configuration that captures wear particles down to 4 microns or less, with up to 95+% efficiency. The radial magnetic field design offers offers up to 10 times more holding capacity than traditional filters.

Benefits

» Optimal hydraulic system reliability

» Increased hydraulic equipment operating capability

» Reduced touchpoints by extending cleaning intervals from 6 to 12 months

» Minimal storage, replacement and disposal of filter elements

» Holding capacity up to 4 lb or 1.8 kg

» Reduced parts replacement

» Minimal maintenance requirements

» Designed for all HPU size requirements

3-Stage Magnetic Filtration

STAGE 1:

PUMP AND MOTOR PROTECTION

Magnetic Filter Scrubber (suction side)

Captures wear particles under 4 microns that easily damage pump and motor components. Contamination builds up in reservoirs as

a sludge. If left unfiltered, it will wear on components causing failures. The suction scrubber is screenless and operates with minimal differential pressure. It is low profile in comparison to a magnetic Y-Strainer, making it ideal for installation after the reservoir to protect the pump and motor components.

STAGE 2:

OUTGOING FLUID PROTECTION

Magnetic Filter Scrubber (pressure side)

Once circulated through the HPU, fluids should proceed through a final filtration to protect valves and actuators from wear debris produced during operation. The magnetic pressure scrubber handles pressures up to 5000 psi and captures wear particles down to 4 microns or less before they continue downstream

STAGE 3:

RETURNING FLUID CONDITIONING

ADD-Vantage 9000 MIT

As fluids return to the reservoir, they require filtration and conditioning to remove the wear contamination produced during hydraulic system operation. The magnetic in-tank filter employs a stainless steel cloth element to capture large dirt particles, and a magnetic filter element that protects against wear particles down to 4 microns or less.

Protect Your Equipment

Download The Ultimate Guide To Fluid Management And Equipment Reliability

4344 12th Street SE Calgary,

AB T2G 3H9 Canada

(403) 242 4221

quotes@oneeyeindustries.com