OEI Core Technology

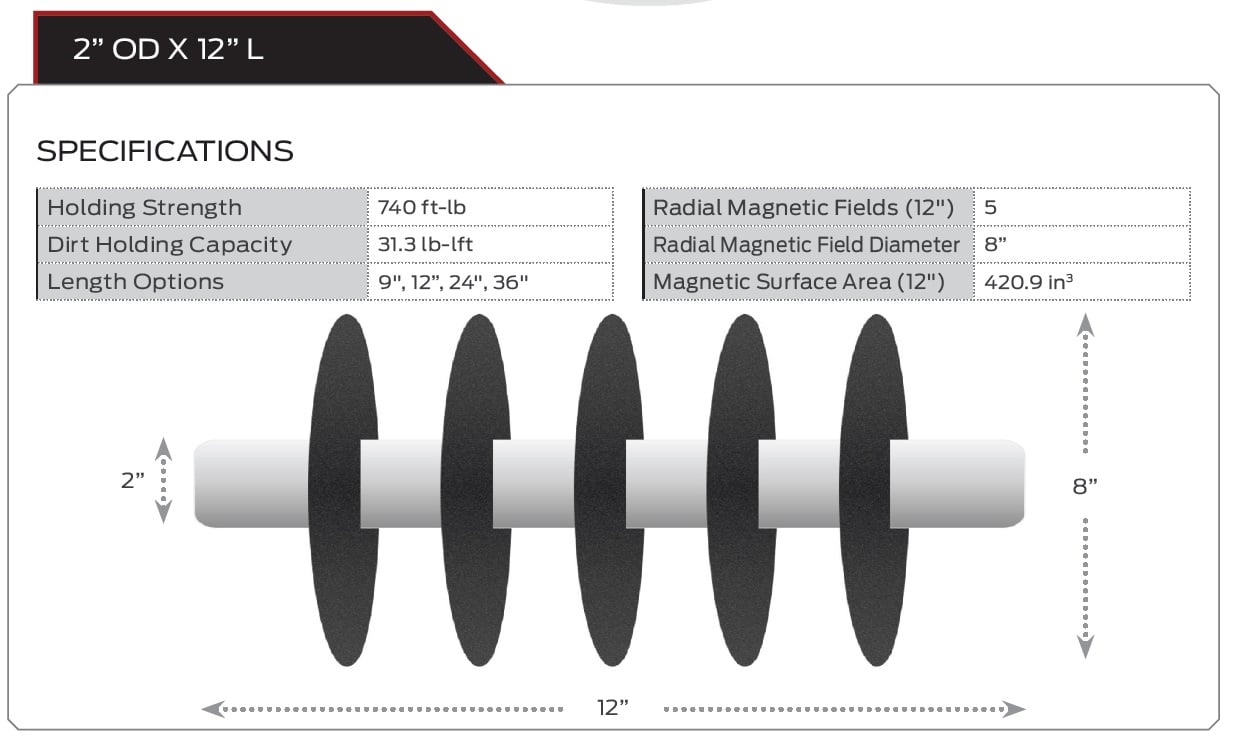

The patented magnetic filter element attracts ferrous wear particles down to 4 microns and below with up to 95+% efficiency. The magnetic filter element attracts both ferrous and non-ferrous particles. The radial magnetic field design offers incredible holding strength and a high dirt holding capacity.

DESCRIPTION

The patented magnetic filter element attracts ferrous wear particles down to 4 microns and below with up to 95+% efficiency. The magnetic filter element attracts both ferrous and non-ferrous particles. The radial magnetic field design offers incredible holding strength and a high dirt holding capacity.

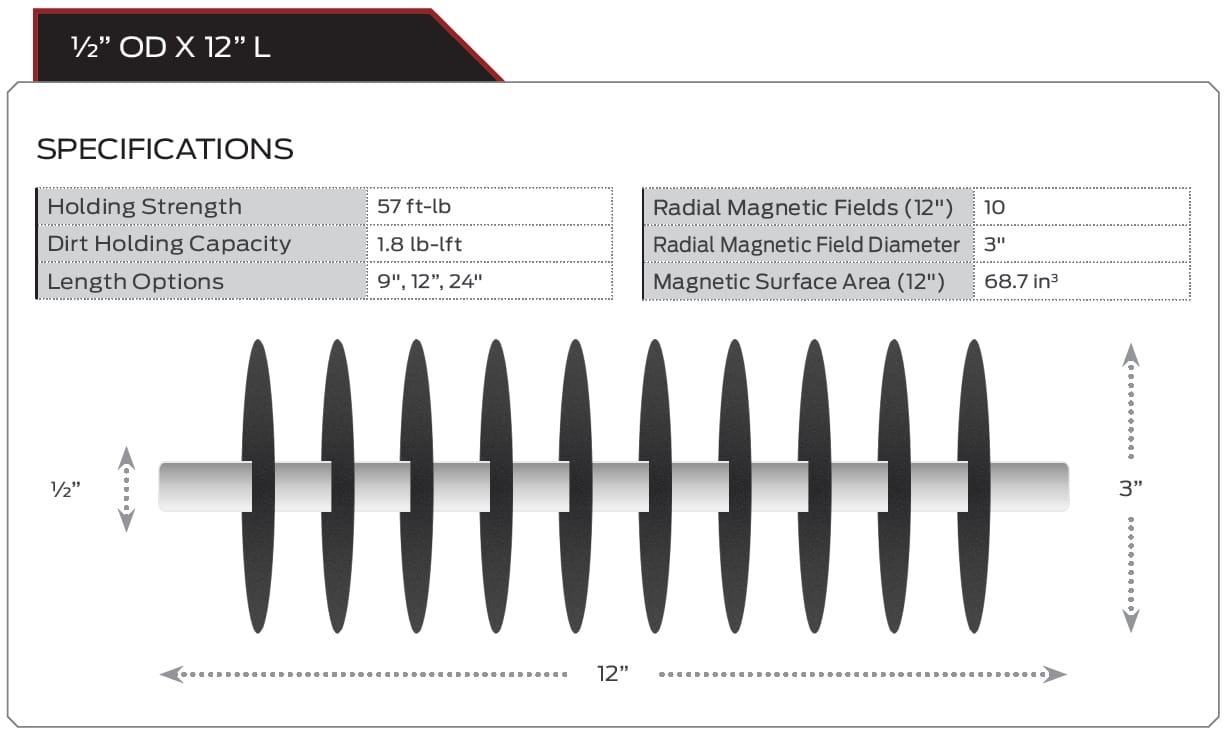

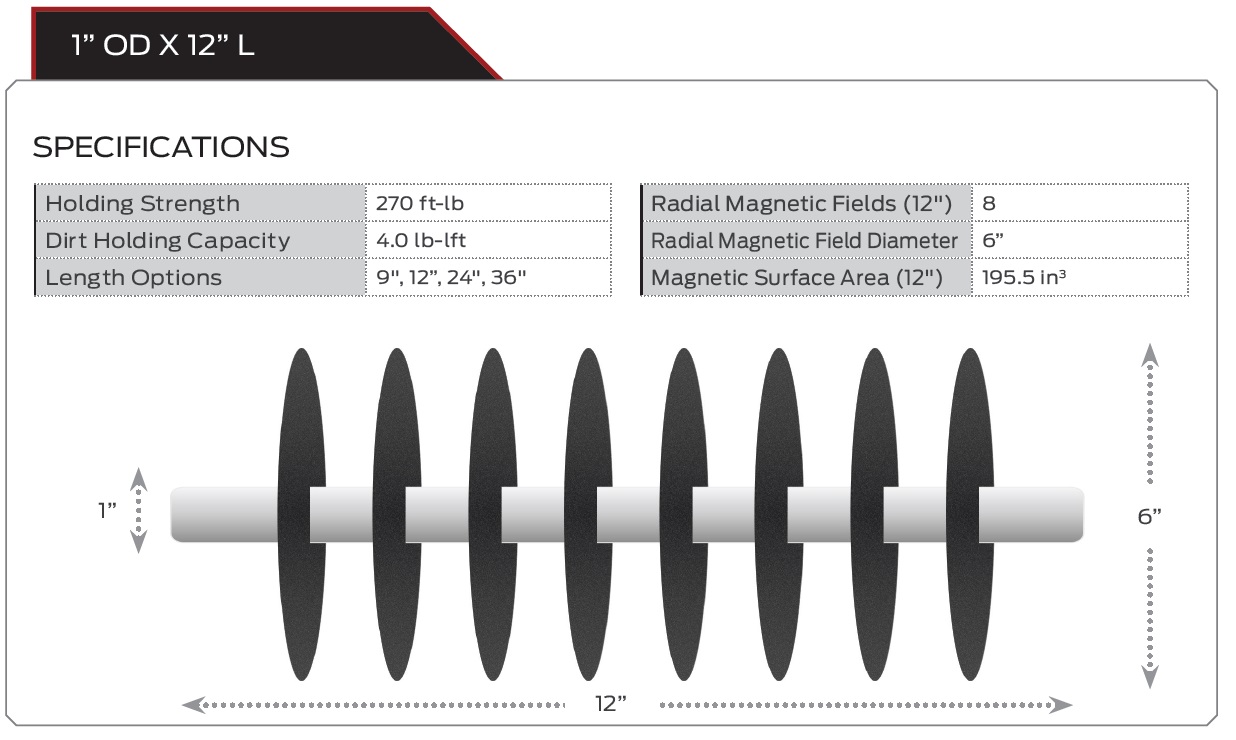

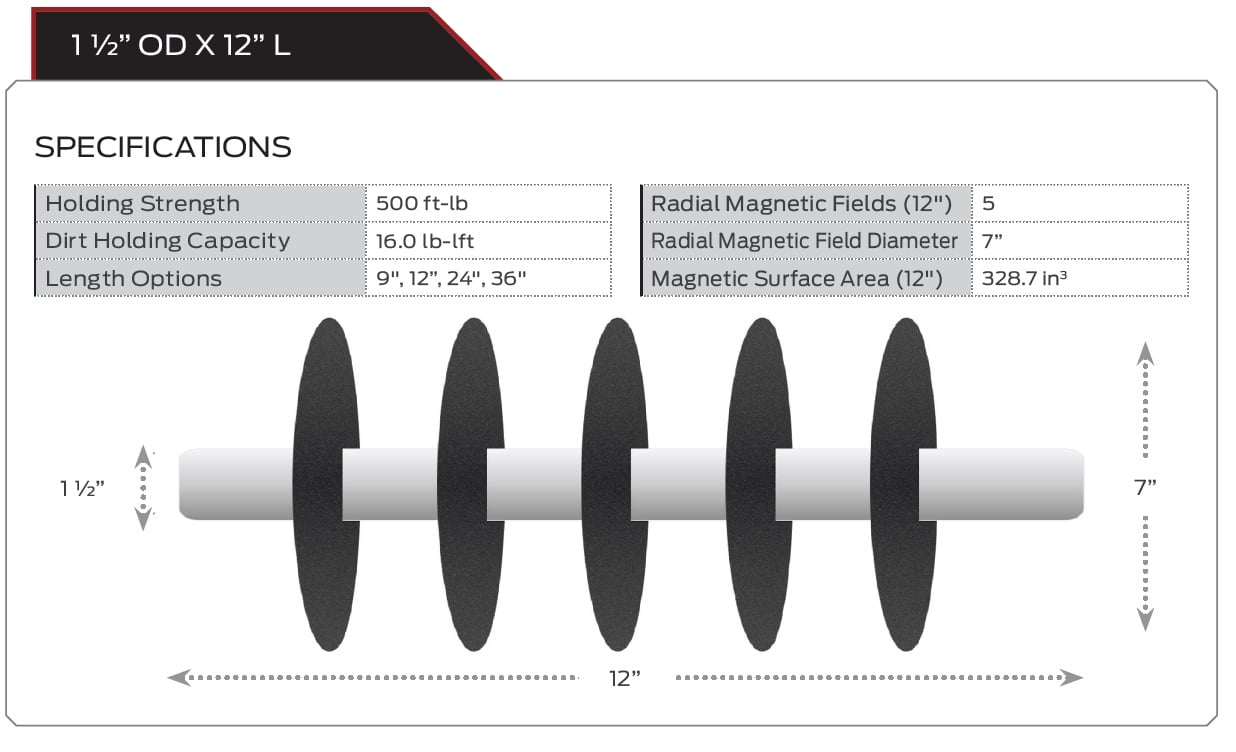

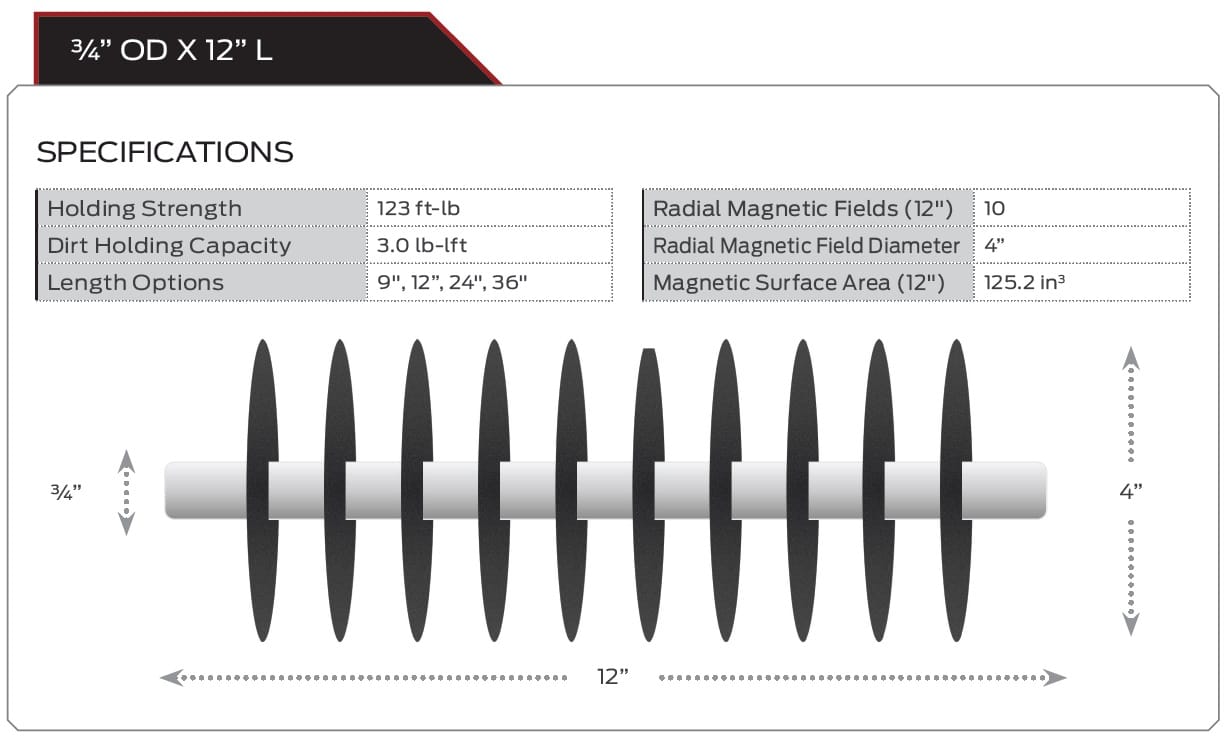

OEI magnetic filter elements are employed in various housings designed with calculated dwell times for optimal filtration. Magnetic filter elements come in five sizes from 1/2” to 2” outer diameter (OD) (shown below).

BENEFITS

CLEAN AND REUSE

- OEI products are reusable for 18+ years, and require minimal consumables. Conventional filters require frequent, costly change outs, and disposal.

PREDICTIVE MAINTENANCE

- OEI Magnetic Filter Elements are effective predictive maintenance tools when used for condition monitoring. When removed for inspection, magnetic filter elements will have varying quantities of contamination. Abnormally high quantities of contamination indicate component failure. The composition of contamination will identify which components are stressed, worn, or failing.

- Visual analysis of the quantities of wear contamination collected on magnetic filter plugs can determine component failure. Analysis of wear particle compositions and sizes will determine early component wear.

GOES WHERE NO CONVENTIONAL FILTER HAS GONE BEFORE

- OEI magnetic filters can be installed on suction lines to protect pumps without risk of cavitation.

Unlike conventional filters, they accommodate space restrictions and unique applications such as

splash oil gearboxes, reservoirs, and small coolant lines.

CAPTURES NON-FERROUS CONTAMINATION

- Non-ferrous particles are magnetically captured because of cross-contamination. Particles become statically charged from flow velocity. This charge is a principal force of particle adhesion; iron particles contaminate non-ferrous particles by adhering to their statically charged surface. Another form of cross-contamination occurs when sub-micron iron particles embed in softer non-ferrous particles after abrasive impact.

PREVENT OXIDIZATION AND VARNISH

- OEI effectively removes iron and steel particles under 10 microns that are known to promote oil oxidation because of their catalytic properties. Oxidation can deplete additives that protect against wear, corrosion, sludge, varnish, and viscosity changes that affect the thickness of films between bearing surfaces, friction, control of temperature, and energy consumption.

NO WORMHOLING OR CHANNELING

- OEI filters eliminate the opportunity for wormholing and channeling that conventional paper,

fiberglass, and polymer media filter elements are subject to.

Wormholing: when wear contamination punctures the filter media.

Channeling: when fluid flows through punctured holes because it takes the path of least resistance.

MAGNETIC FILTER ELEMENT

EFFICIENCY

| Ferrous Contamination Filtration | Captures ferrous wear particles down to 4 μ and below with up to 95+% efficiency. |

| Non-Ferrous Contamination Filtration | Non-ferrous particles are magnetically captured because of cross-contamination. Particles become statically charged from flow velocity. This charge is a principal force of particle adhesion; iron particles contaminate non-ferrous particles by adhering to their statically charged surface. Another form of cross-contamination occurs when sub-micron iron particles embed in softer, non-ferrous particles after abrasive impact. |

OPERATING PARAMETERS

| Pressure Rating | Standard | < 34.5 bar (500 psi) |

| High Pressure | < 689.5 bar (10000 psi) | |

| Temperature Rating | Standard | < 150° C (300° F) |

| High Heat | < 300° C (600° F) | |

| Flow Rate | Housing Dependent | |

| Bypass Setting | Continuous |

MATERIALS

| Magnetic Filter Element | Rare-earth magnets are configured in a patented radial field design |

| Casing | Stainless Steel |

CLEANING

Remove the magnetic filter element from the housing, then remove the contamination with a lab cloth/non-fiber cloth that absorbs the contamination. Save the cloth in a sample bag to send for analysis.

Use the magnetic filter element as a predictive maintenance tool by removing contamination with a lab cloth or rubber glove and depositing it into a sample jar. Send the contamination for analysis to determine the source of equipment component wear and prevent system failure.

LIMITED WARRANTY

| Magnetic Filter Element | 3 years |

| Housing and Components | 1 year |

SERVICE LIFE

| Magnetic Filter Element | 18+ years |

| Stainless Steel Cloth Element | 5 years |

Core Technology

download

Protect Your Equipment

Download The Ultimate Guide To Fluid Management And Equipment Reliability

4344 12th Street SE Calgary,

AB T2G 3H9 Canada

(403) 242 4221

quotes@oneeyeindustries.com