Dispensers

Lube Oil Reservoir Filtration

The challenge was to improve the Mobil 220 lube oil cleanliness to prevent unscheduled downtime and extend equipment life.

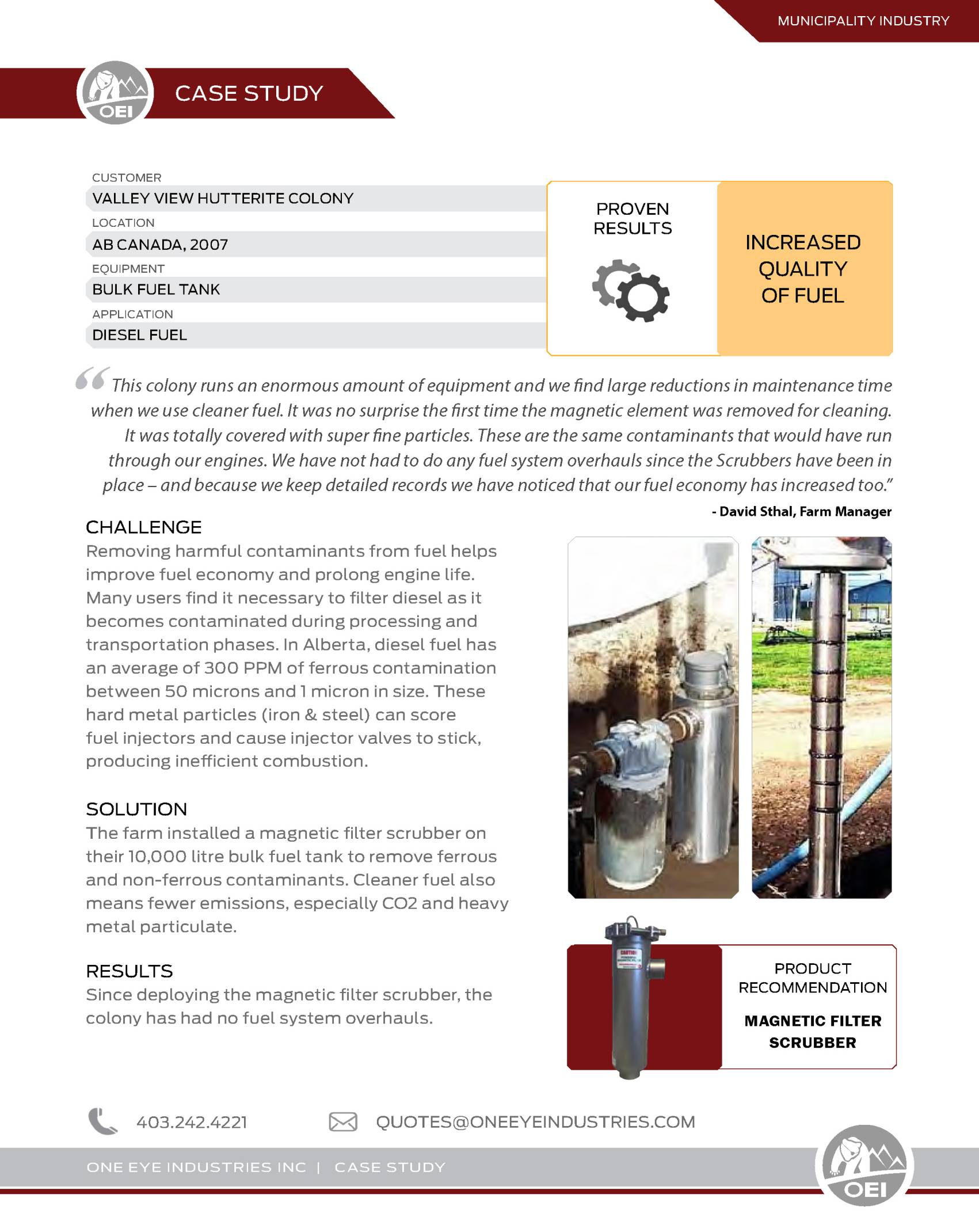

Valley View Farm Bulk Diesel Fuel Dispenser

Removing harmful contaminants from fuel helps improve fuel economy and prolong engine life. Many users find it necessary to filter diesel as it becomes contaminated during processing and transportation phases. In Alberta, diesel fuel has an average of 300 PPM of ferrous contamination between 50 microns and 1 micron in size. These hard metal particles (iron & steel) can score fuel injectors and cause injector valves to stick, producing inefficient combustion.

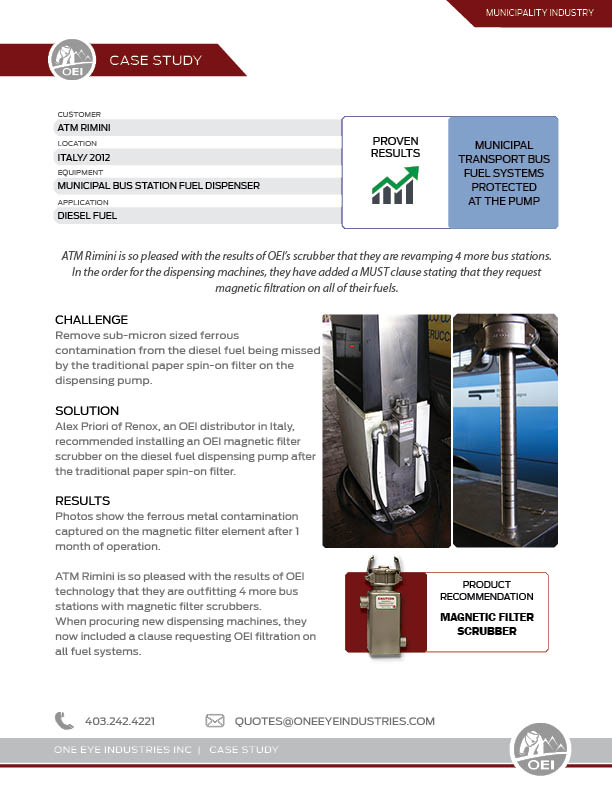

Public Transport Bus Oil Change Extention

The challengve was to remove sub-micron sized ferrous contamination from the diesel fuel being missed by the traditional paper spin-on filter on the dispensing pump.

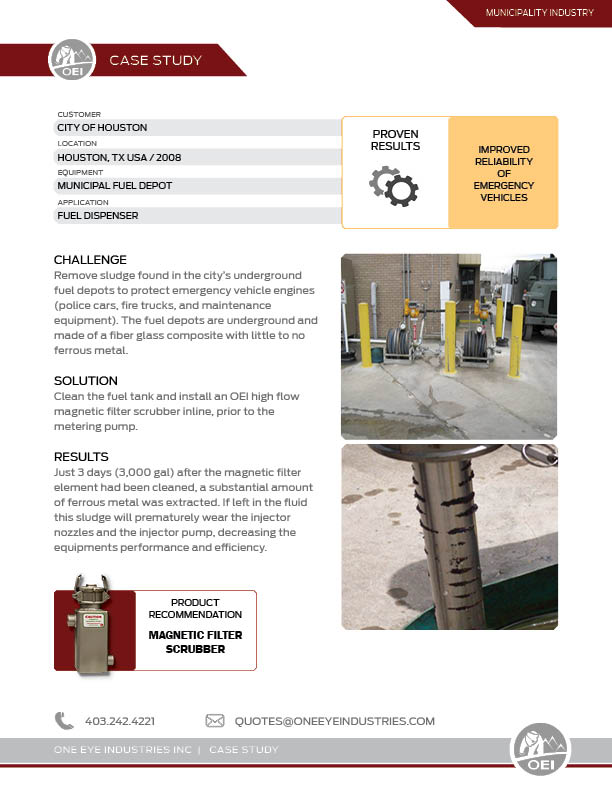

Keeping Houston’s Emergency Vehicles in Service

The challenge was to remove sludge found in the city’s underground fuel depots to protect emergency vehicle engines (police cars, fire trucks, and maintenance equipment). The fuel depots are underground and made of a fiber glass composite with little to no ferrous metal.

ColoWyo Mine Protecting Tier 3 and 4 Engines

Out of concern for the new tier 3 and 4 engine tolerances, Colowyo wanted to improve their diesel fuel engine cleanliness to minimize ianjector and pump wear.

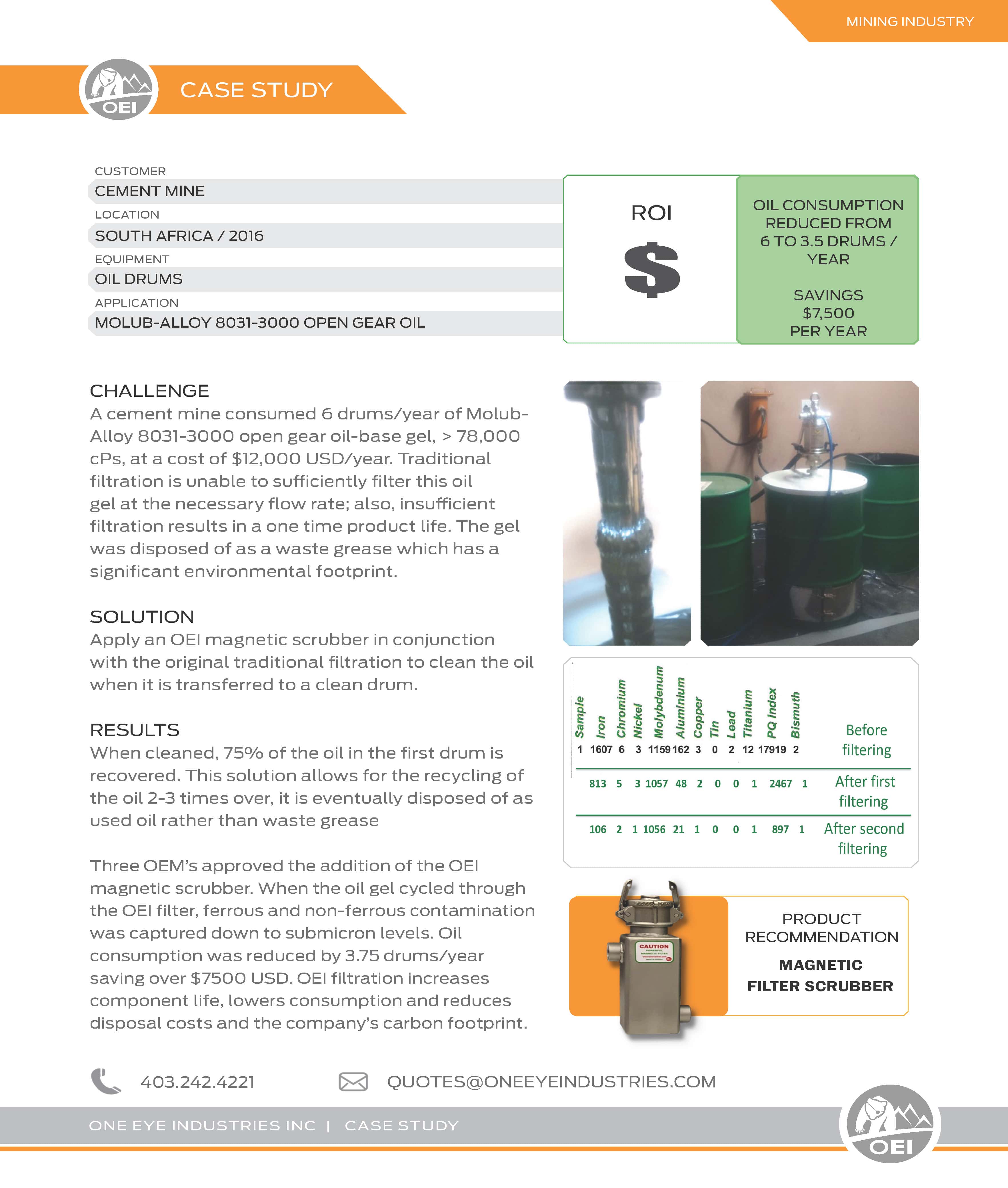

Filtering Heavy Lube Oil in Drums to Save Thousands

A cement mine consumed 6 drums/year of Molub-Alloy 8031-3000 open gear oil-base gel, > 78,000 cPs, at a cost of $12,000 USD/year. Traditional filtration is unable to sufficiently filter this oil gel at the necessary flow rate; also, insufficient filtration results in a one time product life. The gel was disposed of as a waste grease which has a significant environmental footprint. The challenge was to clean the oil when it is transferred to a clean drum.

Consol Energy Corp Diesel Fuel Dispensing

The challenge was to protect mining equipment from wear contamination under 4 microns that would damage close tolerance fuel system components; filter the diesel fuel coming out of the tanks, prior to dispensing.

IOCC High Flow Diesel Fuel Line Filtration

IIOC was concerned with their diesel fuel meeting higher-tier engine fuel cleanliness requirements. Existing fuel cleanliness aligned with North American fuel delivery standards, however, IOCC wanted to improve on the cleanliness in order to minimise on injector and pump component wear.

Weatherford Colombia Diesel Fuel Dispenser

Weatherford Colombia was finding high levels of ferrous contamination in their diesel fuel. Equipment running on the dirty fuel required sub-micron level filtration; without it, the equipment was experiencing premature wear of fuel system components, reduced burn efficiency and increased emissions.

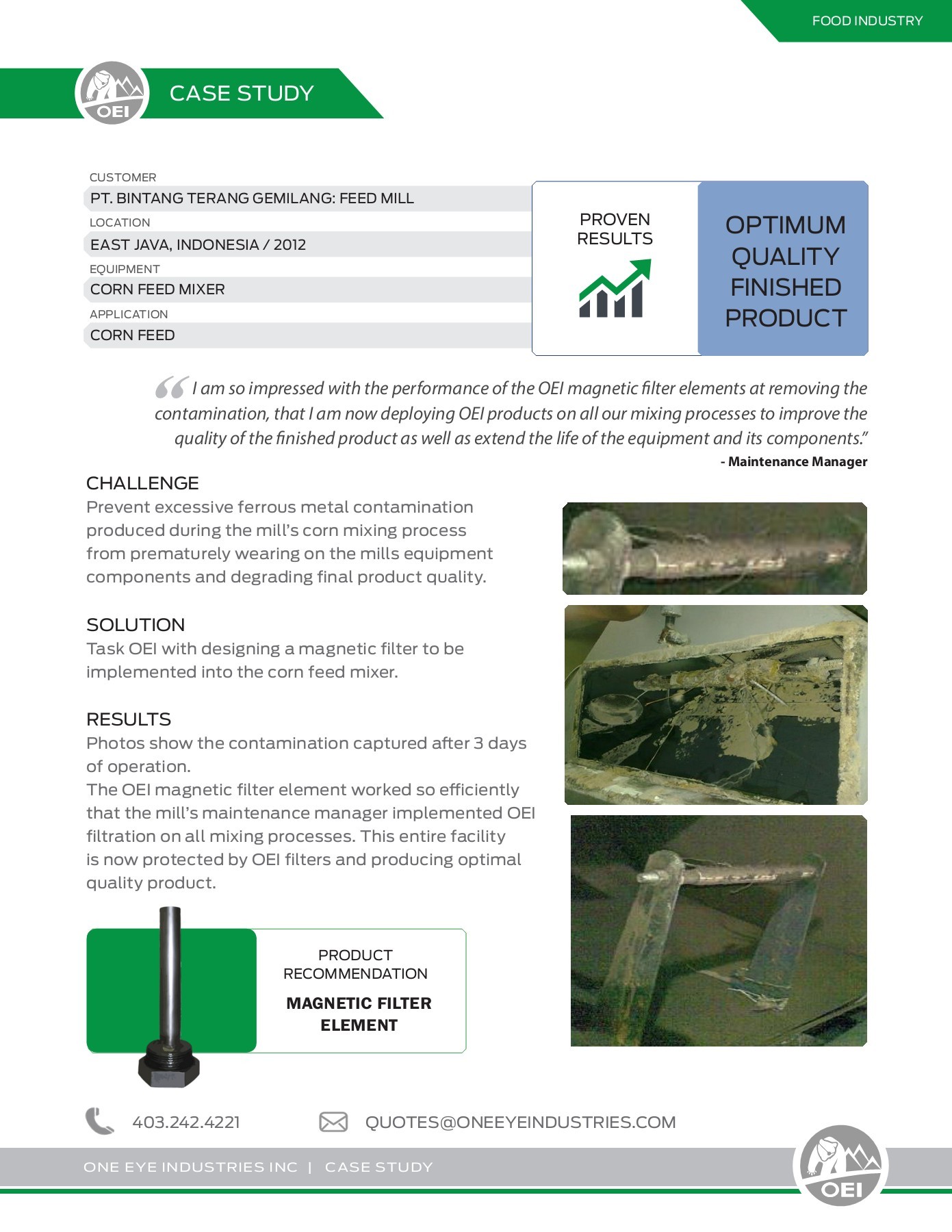

Indonesia Corn Feed Mixer

The challenge was to prevent excessive ferrous metal contamination produced during the mill’s corn mixing process from prematurely wearing on the mills equipment components and degrading final product quality.

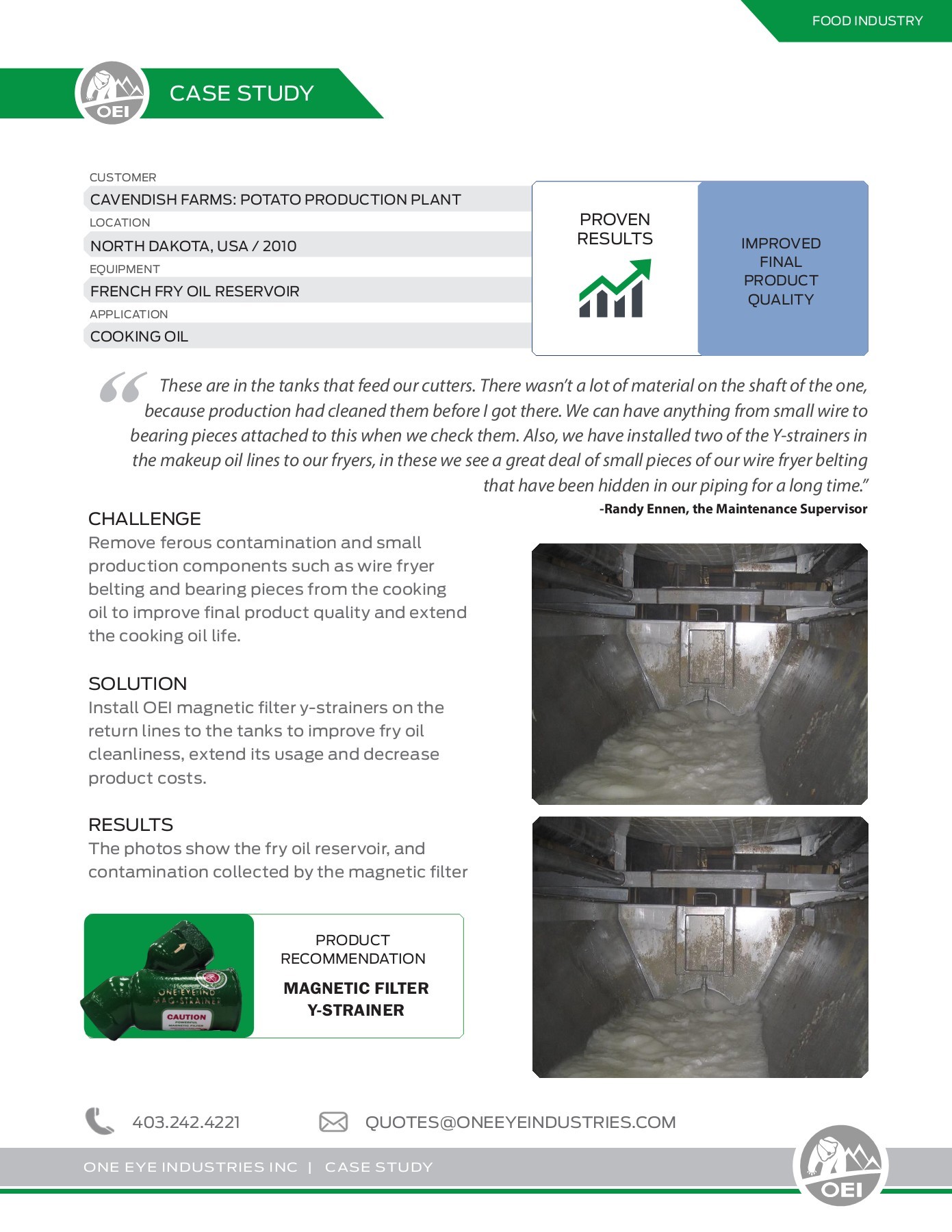

Cavendish Farms Fry Oil Reservoir

The challenge was to remove ferous contamination and small production components such as wire fryer belting and bearing pieces from the cooking oil to improve final product quality and extend the cooking oil life.

OEI magnetic filters are designed for 95+% efficiency: they are optimized for fluid viscosity, flow volume, flow rate, temperature, mobility, and mounting requirements.

Use of the OEI Data Form will provide the necessary specifications for OEI to determine which product is right for you

REQUEST A QUOTE

4344 12th Street SE Calgary,

AB T2G 3H9 Canada

(403) 242 4221

quotes@oneeyeindustries.com