Milling Machines

Improve the quality of cooling/cutting oil, extend operating life, ensure efficient heat transfer, prevent re-cutting or welding of filings, and reduce the risk of tooling fracture.

Gildermiester Milling Machine Cooling Fluid Filtration

The challenge was to prevent metal filings from filling the cooling system to avoid overheating and shutdown. The traditional filtration in the Gildermeister machine’s cooling system was not providing effective filtration and, therefore, the machine’s radiator was filling with metal filings. As a result, the machine was running at temperatures from 32-34 degrees Celsius (shut down would occur at 35 degrees). This was causing frequent unscheduled downtime for cooling system maintenance.

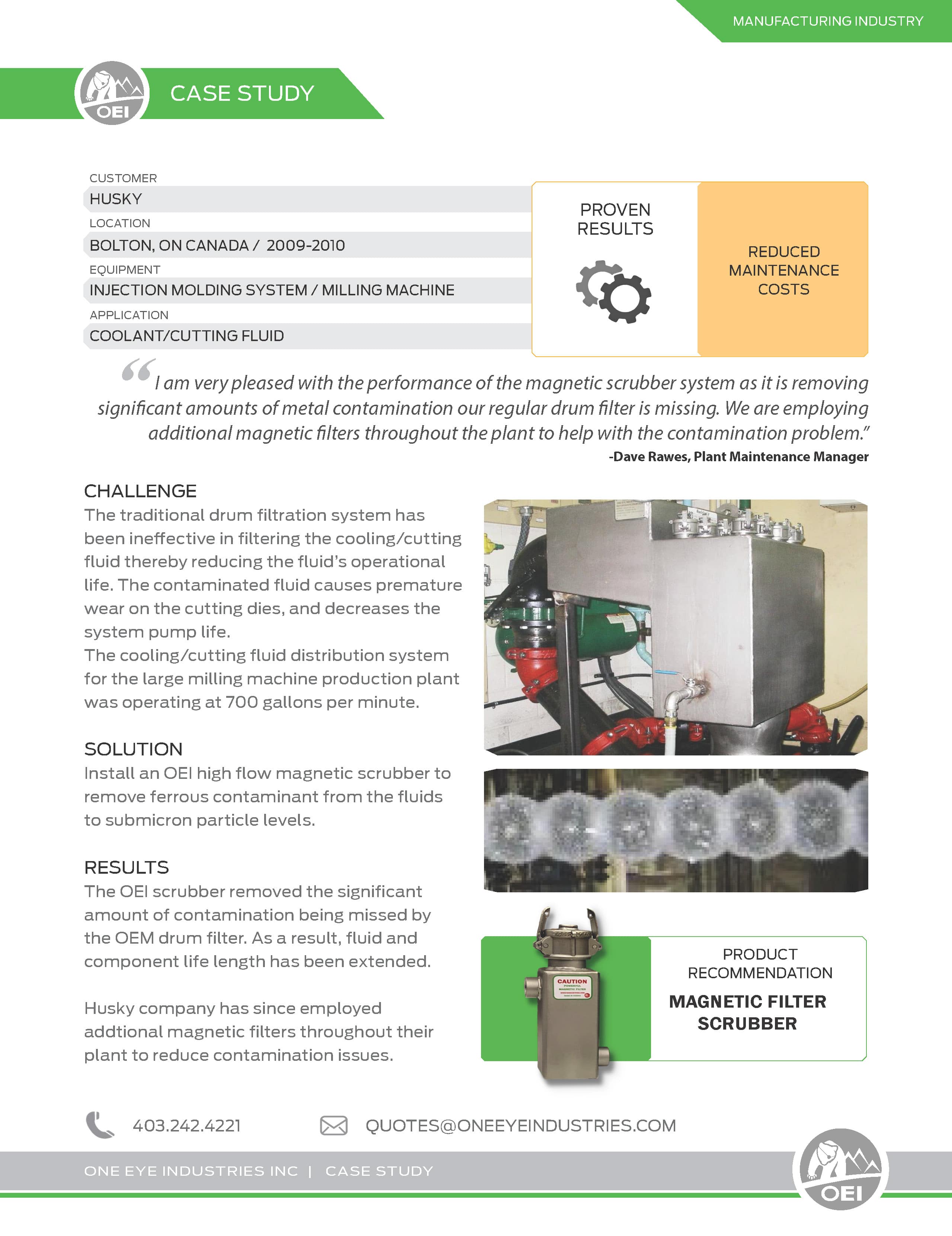

Husky’s Injection Molding System Protection

The traditional drum filtration system was ineffective in filtering the cooling/cutting fluid thereby reducing the fluid’s operational life. The contaminated fluid caused premature wear on the cutting dies, decreasing the system pump life. The challenge was to remove ferrous contaminant from the fluids to submicron particle levels.

OEI magnetic filters are designed for 95+% efficiency: they are optimized for fluid viscosity, flow volume, flow rate, temperature, mobility, and mounting requirements.

Use of the OEI Data Form will provide the necessary specifications for OEI to determine which product is right for you

REQUEST A QUOTE

4344 12th Street SE Calgary,

AB T2G 3H9 Canada

(403) 242 4221

quotes@oneeyeindustries.com