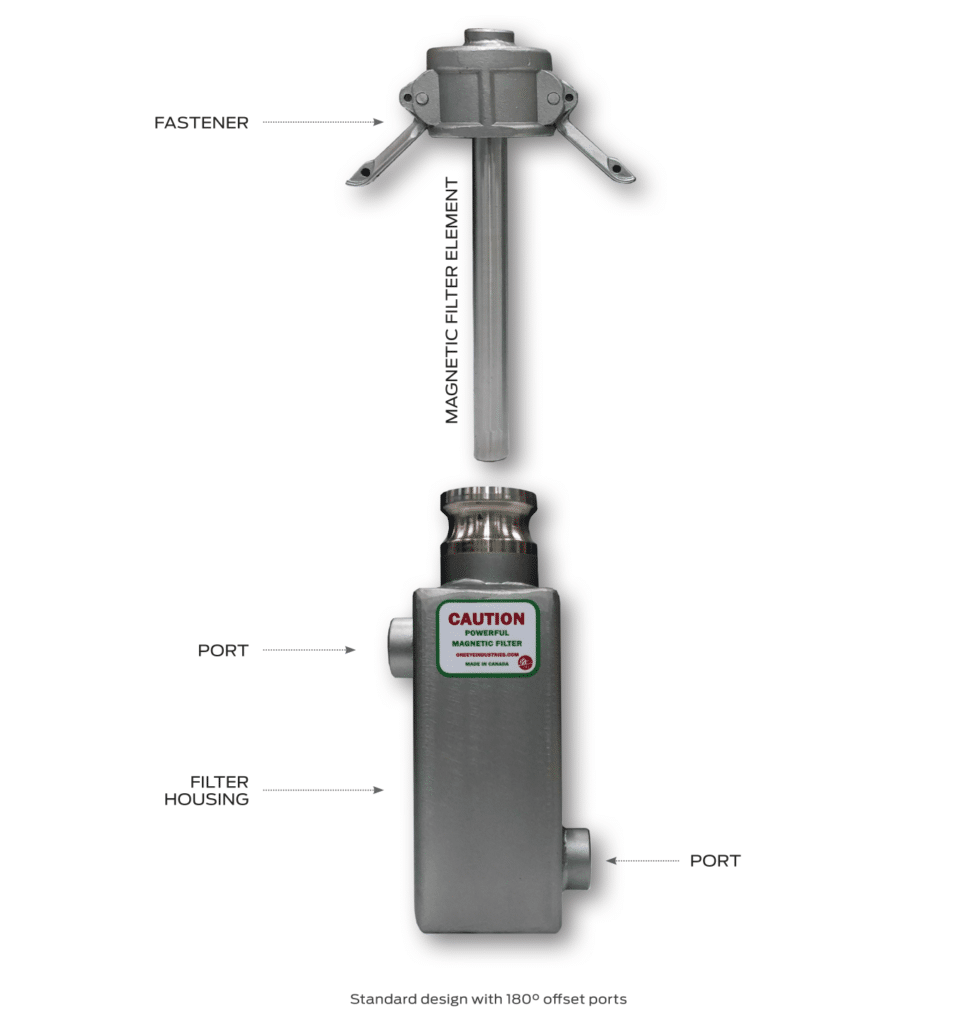

Magnetic Filter Scrubber

Magnetic filter scrubbers employ a magnetic filter element in a specialty housing designed to operate with minimal flow restriction and maximum fluid exposure for high-efficiency filtration. Flow is regulated by the diameter of the inlet-outlet supply pipe as well as fluid velocity. These systems install on suction and return lines of high-pressure and low-pressure applications.

Description

Magnetic filter scrubbers employ a magnetic filter element in a specialty housing designed to operate with minimal flow restriction and maximum fluid exposure for high-efficiency filtration. Flow is regulated by the diameter of the inlet-outlet supply pipe as well as fluid velocity. These systems install on suction and return lines of high-pressure and low-pressure applications.

Benefits

» Minimal flow restriction allows for suction line installation and pump protection.

» High holding capacity allows for extended planned maintenance periods.

» Continuous filtration in bypass

» Acts as an effective predictive maintenance tool if contamination is collected and analyzed to determine sources of equipment component wear.

Efficiency

| Magnetic Filter Element | Ferrous Contamination | Captures ferrous wear particles down to 4 μ and below with up to 95+% efficiency. |

| Non-ferrous Contamination | Non-ferrous particles are magnetically captured because of cross-contamination from static charge or embedded ferrous particles. |

Operating Parameters

| Pressure / Temperature Rating | Standard | < 10.3 bar (150 psi) @ < 105° C (221° F) |

| High Heat | < 34.4 bar (500 psi) @ < 204.4° C (400° F) | |

| Standard | < 680 cSt | |

| Viscosity Rating | Low Viscosity | < 2,000 cSt |

| Bypass Settings | Continuous filtration with no internal bypassing |

Cleaning

Magnetic Filter Element: Remove the contamination by wiping downward with a lab cloth or rubber glove.

Use the magnetic filter element as a predictive maintenance tool by removing contamination with a lab cloth or rubber glove and depositing it into a sample jar. Send the contamination for analysis to determine the source of equipment component wear and prevent system failure.

Materials

| Magnetic Filter Element | Rare-earth magnets configured in a patented radial field design. | |

| Filter Housing, Drain Plugs, End Caps, Mounts | Standard | Stainless Steel |

| Specialty Materials | »» Monel »» Other alloys available | |

| Seals | Standard Heat | Buna |

| HIgh Heat | Viton | |

| Sub-zero | EDPM |

Configurations

| Magnetic Filter Element | Quantities | »» Single »» Dual | »» Dual Inline »» Triple | »» Quadruple | |

| Lengths | »» 9” | »» 12" | »» 24" | »» 36" | |

| Housings | Square | < 10.3 bar (150 psi) | |||

| Round | < 34.4 bar (500 psi) | ||||

| Fasteners | Cam-lock | < 10.3 bar (150 psi) | |||

| ORB, Flange | < 34.4 bar (500 psi) | ||||

| Ports | »» Inline | »» Parallel Ports | »» Upper housing | »» Lower housing | |

| »» Offset | »» 0° Offset | »» 90° Offset | »» 180° Offset | »» 270° Offset | |

| »» Multi-port | »» Manifold |

| Magnetic Filter Element | Quantities | »» Single »» Dual »» Dual Inline »» Triple »» Quadruple |

| Lengths | »» 9” »» 12" »» 24" »» 36" |

| Housings | Square | < 10.3 bar (150 psi) |

| Round | < 34.4 bar (500 psi) |

| Fasteners | Cam-lock | < 10.3 bar (150 psi) |

| ORB, Flange | < 34.4 bar (500 psi) |

| Ports | »» Inline | »» Parallel Ports | »» Upper housing | »» Lower housing | |

| »» Offset | »» 0° Offset | »» 90° Offset | »» 180° Offset | »» 270° Offset | |

| »» Multi-port | »» Manifold |

Installation

| Port Size Custom sizes available | 1/2” - 2 1/2” | |||

| Port Type | »» NPT »» ORB | »» CD61 »» CD62 | »» BSPT »» BSPP | »» Flange |

| Mount Type | »» Inline | »» Vertical | »» Horizontal | |

| Element Clearance | Housing length + 4” |

Limited Warranty

| Magnetic Filter Element | 3 years |

| Housing and Components | 1 year |

Service Life

| Magnetic Filter Element | 18+ years |

Magnetic Filter Scrubbers

download

Series Specifications

| TYPE | DESCRIPTION | PART NUMBER | PRESSURE RATING | TEMP. RATING | HOUSING SIZE | MAGNETIC FILTER ELEMENT | |

| LOW PRESSURE | OEI standard magnetic filter scrubber is designed with a square housing, typically with a camlock fastener. These units install with multiple port size, location, and fitting options. | 5SC349S | < 10.3 bar (150 psi) | 105° C (221° F) | 3” L x 3” W x 9” H | 3/4” OD | |

| 5SC12S | < 10.3 bar (150 psi) | 105° C (221° F) | 4” L x 4” W x 12” H | 1” OD | |||

| 5SC24S | < 10.3 bar (150 psi) | 105° C (221° F) | 4” L x 4” W x 24” H | 1” OD | |||

| MEDIUM PRESSURE | Fluid applications requiring pressures over 150 psi are designed with a round housing and ORB, or flange fastener. | 5SC349RORB | < 34.4 bar (500 psi) | 105° C (221° F) | 3” OD x 9” H | 3/4” OD | |

| 5SC12RORB | < 34.4 bar (500 psi) | 105° C (221° F) | 4” OD X 12” H | 1” OD | |||

| 5SC24RORB | < 34.4 bar (500 psi) | 105° C (221° F) | 4” OD x 24” H | 1” OD | |||

| HIGH PRESSURE | Designed for high pressure applications up to 5000 psi. | 5SMP | < 206.8 bar (3000 psi) | 75° C (167° F) | 3 1/2” OD x 17” H | 1” OD | |

| 5SHP | < 344.7 bar (5000 psi) | 75° C (167° F) | 3 1/2” OD x 17” H | 1” OD | |||

| SPECIALTY | INLINE | With a billet aluminum housing, this scrubber installs inline for low-pressure, light viscosity, low-flow applications | 5IL04 | 6.9 bar (100 psi) | 105° C (221° F) | 2 1/4” OD x 6” H | 1/2” OD |

| 5IL05 | 6.9 bar (100 psi) | 105° C (221° F) | 2 1/4” OD x 7 1/4” H | 3/4” OD | |||

| 5IL905 | 6.9 bar (100 psi) | 105° C (221° F) | 2 1/4” OD x 9 1/4” H | 3/4” OD | |||

| FUNNEL | This scrubber installs inline on food and material production lines. | 4FS# | 24.1 bar (350 psi) | 121.1° C (250° F) | 4” OD x 27" H | 1” OD |

Protect Your Equipment

Download The Ultimate Guide To Fluid Management And Equipment Reliability

4344 12th Street SE Calgary,

AB T2G 3H9 Canada

(403) 242 4221

quotes@oneeyeindustries.com