Building Operations

Boilers, chillers, water loops, and heat exchangers all require quality filtration of hard particles (iron, silica, sodium) under 5 microns to protect their tight tolerance components from wear and eventual failure. Poor water quality directly results in increased maintenance and downtime.

Featured Case Study

Proven Result:

-

1800+ fewer filters to the landfill annually

-

Filter savings $10,560/ year (1820 filters/ year)

-

Labour savings $13,920/ year (696 hours/ year)

Customer

The Bow Tower

Location

Calgary

Equipment

Office Tower

Application

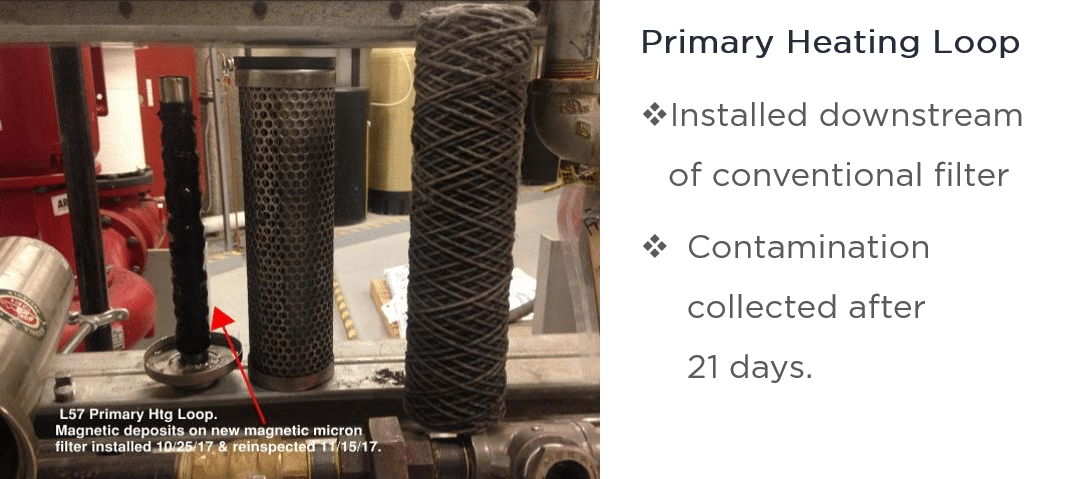

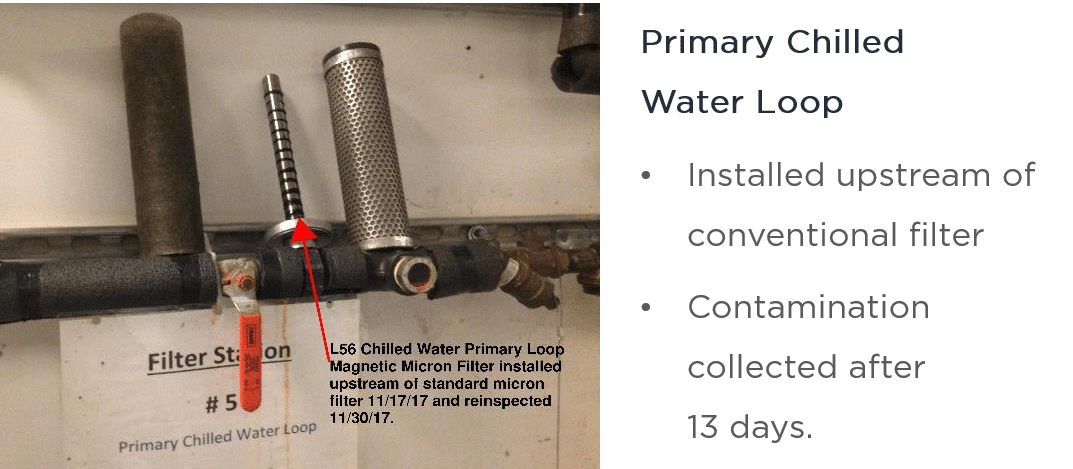

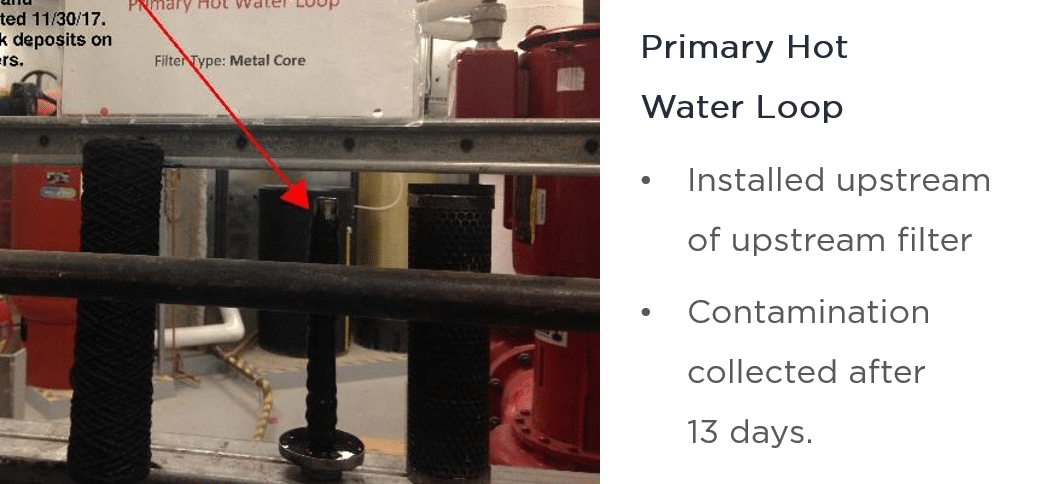

Condenser Water Loop, Glycol Loop, Cooling Tower, Primary Chilled Water Loop, Primary Heated Loop

Challenge

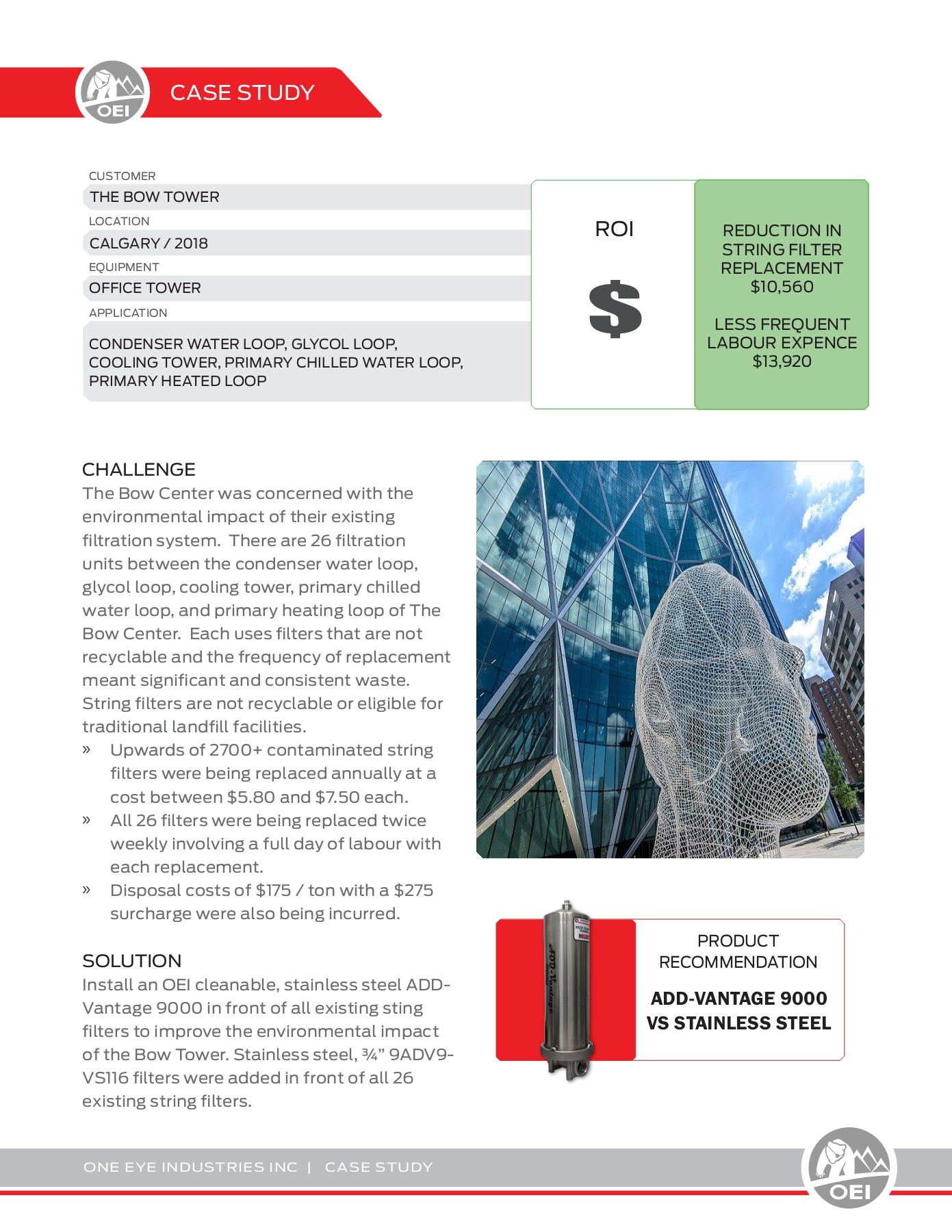

The Bow Center was concerned with the environmental impact of their existing filtration system. There are 26 filtration units between the condenser water loop, glycol loop, cooling tower, primary chilled water loop, and primary heating loop of The Bow Center. Each uses filters that are not recyclable and the frequency of replacement meant significant and consistent waste.

String filters are not recyclable or eligible for traditional landfill facilities.

- Upwards of 2700+ contaminated string filters were being replaced annually at a cost between $5.80 and $7.50 each.

- All 26 filters were being replaced twice weekly involving a full day of labour with each replacement.

- Disposal costs of $175 / ton with a $275 surcharge were also being incurred.

Solution

Install an OEI cleanable, stainless steel ADD-Vantage 9000 in front of all existing sting filters to improve the environmental impact of the Bow Tower. Stainless steel, ¾” 9ADV9-VS116 filters were added in front of all 26 existing string filters.

Results

The addition of OEI filtration has significantly reduced the number of filters The Bow Center is sending to the landfill each year.

Condenser loop, glycol loop, and chilled water loop filters are checked weekly and string filters now last over one month before requiring replacement.

The new filtration process means a reduction in annual filter costs from $15,680 to $5,130, a savings of $10,550 (year 1); because OEI filters are a one time purchase, the annual filter replacement savings increases to $15,690 each following year.

Annual labour costs reduced from $16,640 to $2,720, a savings of $13,920.

The Bow tower is also seeing 1% of sand removed from the cooling tower every 2 days.

Building Operations

RESULTS

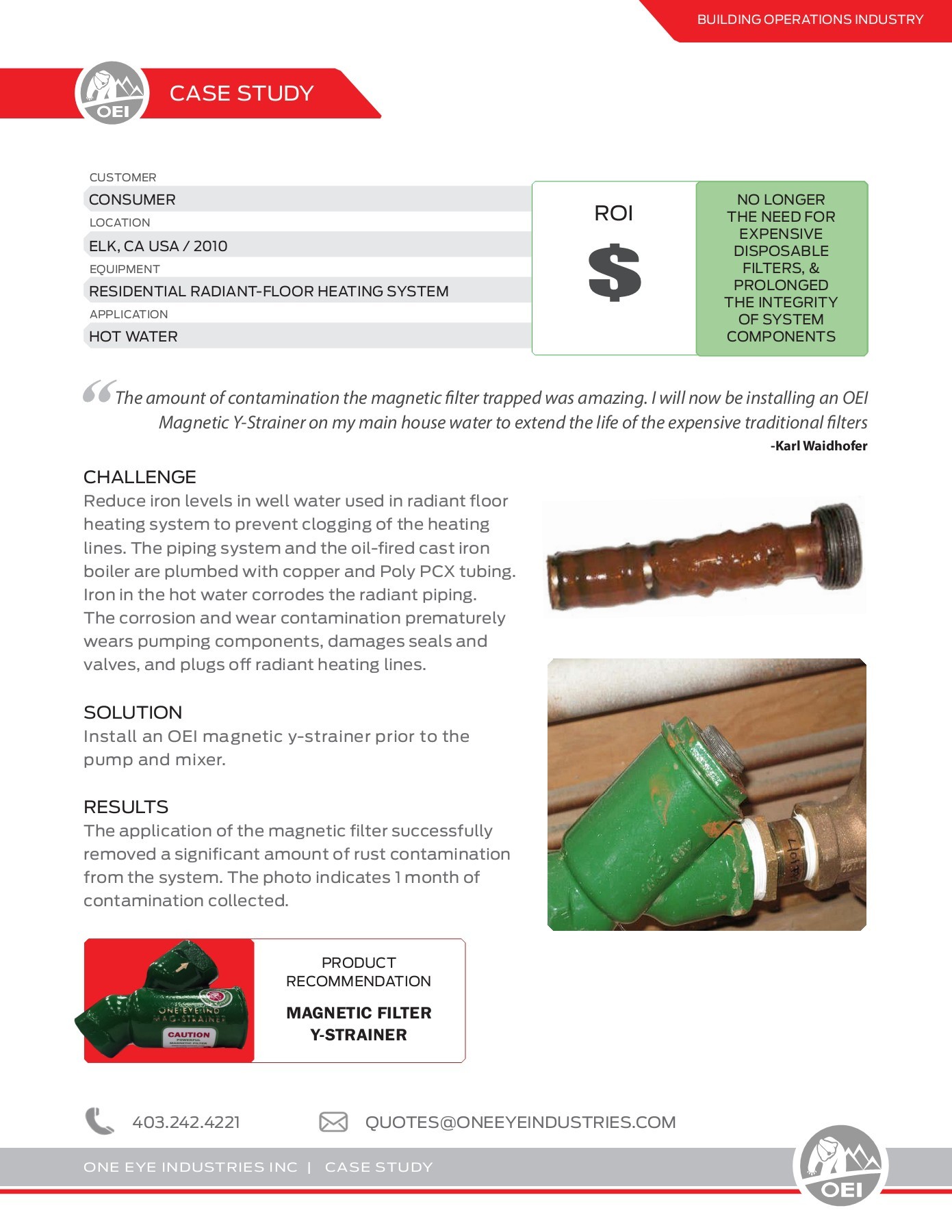

Radiant Floor Heating System Reliability

The challenge was to reduce iron levels in well water used in radiant floor heating system to prevent clogging of the heating lines. The piping system and the oil-fired cast iron boiler are plumbed with copper and Poly PCX tubing. Iron in the hot water corrodes the radiant piping. The corrosion and wear contamination prematurely wears pumping components, damages seals and valves, and plugs off radiant heating lines.

BOW Center HVAC Outfitting

The Bow Center was concerned with the environmental impact of their existing filtration system. There are 26 filtration units between the condenser water loop, glycol loop, cooling tower, primary chilled water loop, and primary heating loop of The Bow Center. Each uses filters that are not recyclable and the frequency of replacement meant significant and consistent waste. String filters are not recyclable or eligible for traditional landfill facilities.

- Upwards of 2700+ contaminated string filters were being replaced annually at a cost between $5.80 and $7.50 each.

- All 26 filters were being replaced twice weekly involving a full day of labour with each replacement.

- Disposal costs of $175 / ton with a $275 surcharge were also being incurred.

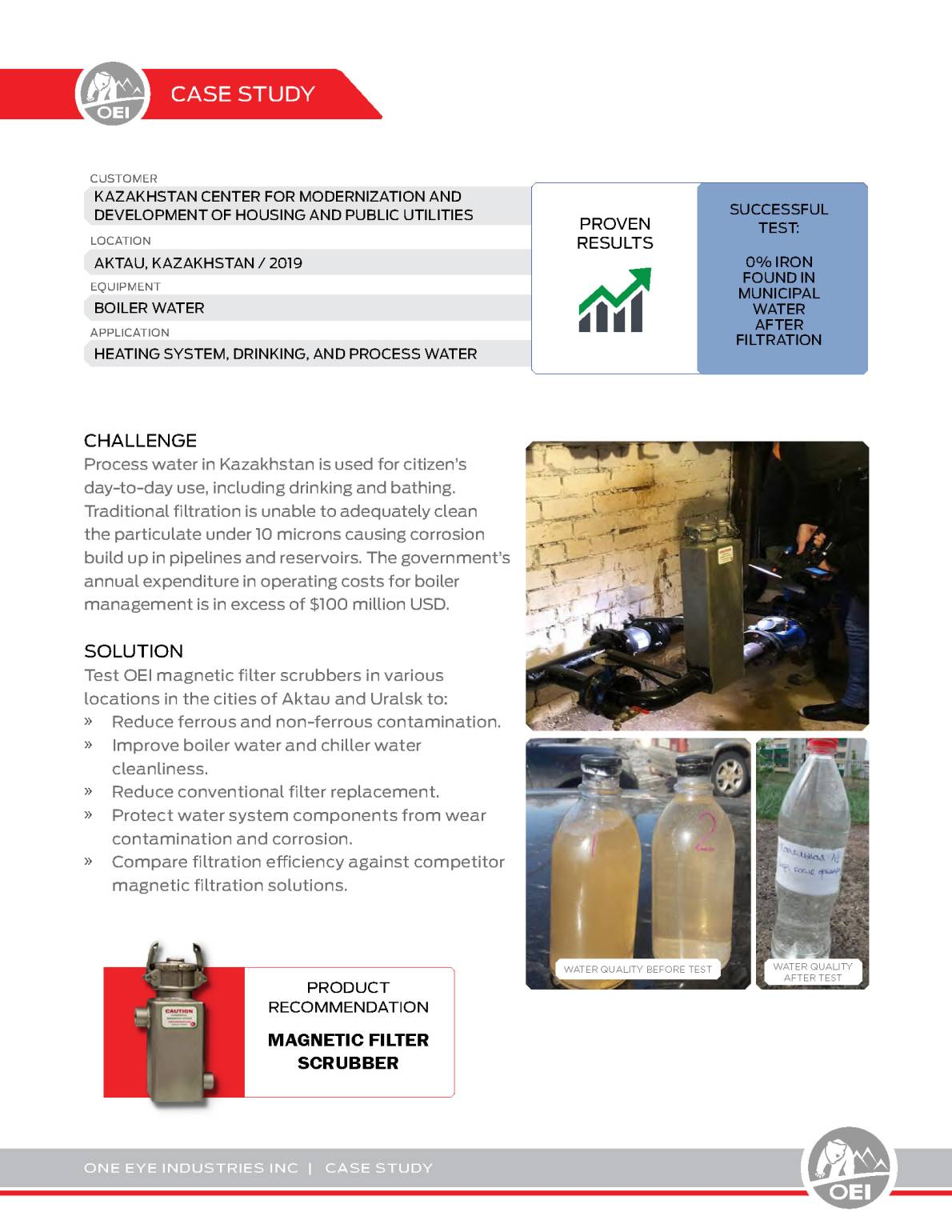

Kazakhstan Municipal Water Quality Test

The challenge was to clean process water in Kazakhstan that is used for citizen’s day-to-day use, including drinking and bathing.

Traditional filtration is unable to adequately clean the particulate under 10 microns causing corrosion build up in pipelines and reservoirs. The government’s annual expenditure in operating costs for boiler management is in excess of $100 million USD.

OEI magnetic filters are designed for 95+% efficiency: they are optimized for fluid viscosity, flow volume, flow rate, temperature, mobility, and mounting requirements.

Use of the OEI Data Form will provide the necessary specifications for OEI to determine which product is right for you

REQUEST A QUOTE

4344 12th Street SE Calgary,

AB T2G 3H9 Canada

(403) 242 4221

quotes@oneeyeindustries.com