Engine Lube Oil

Extend service intervals. OEI technology applies to natural gas, diesel fuel, and steam turbine engines. The OEI advantage is high holding capacity filters with continuous filtration in bypass.

Ingerssol High-Pressure Air Compressor

Moisture in the air system was causing corrosion of the carbon-steel piping was producing high levels of contamination in the system. The contamination was prematurely damaging the solenoid valve rubber seals. The damage forced the valves to remain open resulting in the need to replace them monthly. The valve failures were inhibiting production. In an effort to reduce unscheduled downtime and the monthly expense of replacing the valves, the maintenance team removed them all together.

Kinecor Detroit Diesel Engine Oil

The challenge was to improve the cleanliness of the lube oil to protect close tolerance components and extend oil change intervals.

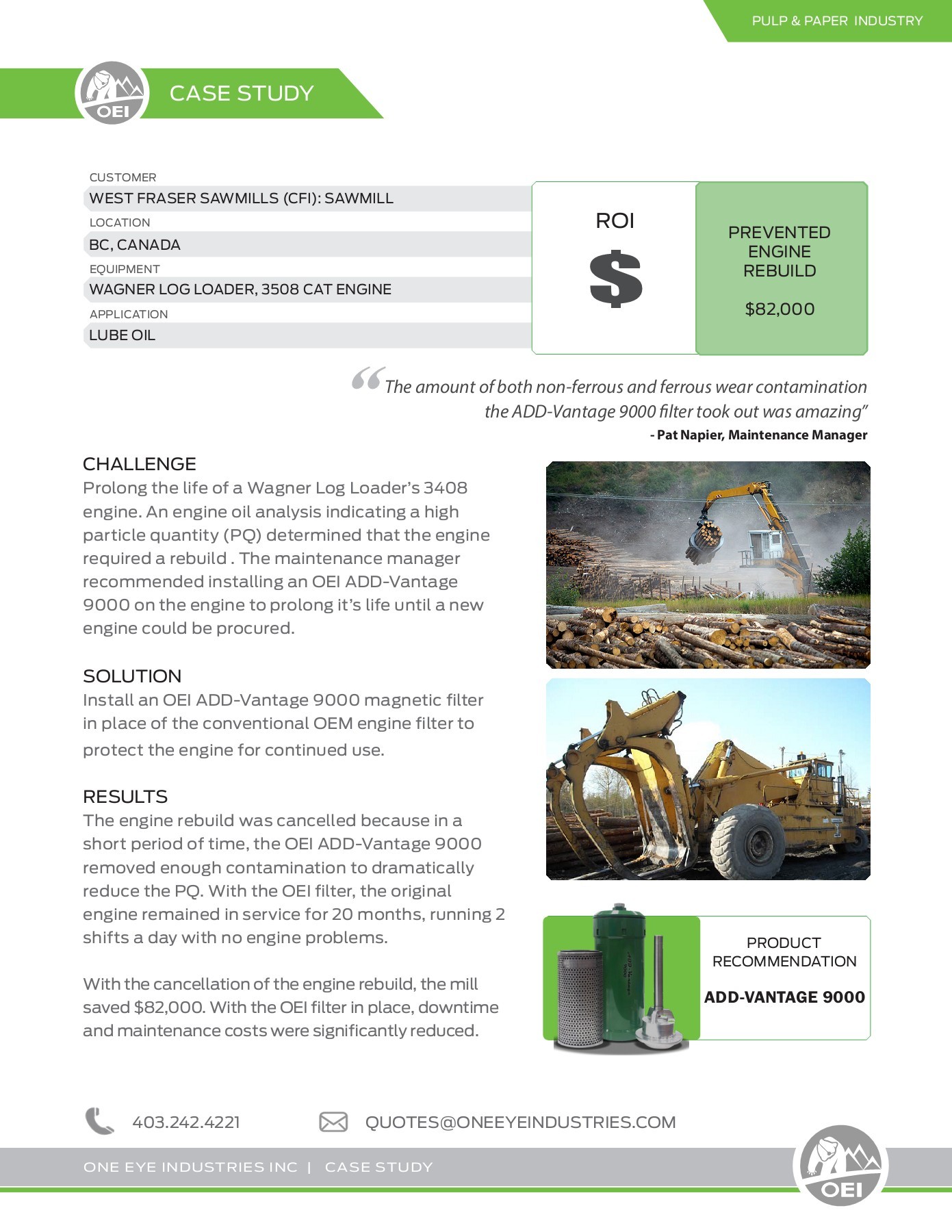

Log Unloader Engine Rebuild Prevention

The challenge was to prolong the life of a Wagner Log Loader’s 3408 engine. An engine oil analysis indicating a high particle quantity (PQ) determined that the engine required a rebuild. The maintenance manager recommended installing an OEI ADD-Vantage 9000 on the engine to prolong it’s life until a new engine could be procured.

600 HP Diesel Locomotive Engine Protection

John Weaver, the Maintenance Manager of the Oilseed Processing Division, was looking for ways to prolong engine oil life of a 600 HP Diesel Locamotive engine that was operating 24/7. John wanted to extend oil change intervals without compromising oil viscosity. Regular maintenance called for the engine oil to be changed every 200 hours of operation. In addition regular checks on engine oil levels called for a gallon of oil to be added every week.

Luxury Yacht Engine Protection

The challenge was to clean the engine oil of wear contamination under 4 microns missed by the yacht’s existing filtration system to prevent it from prematurely wearing engine components. The main sources of contamination are air ingression, engine parts manufacturing, inherent wear particles in new oil, and break-in wear. Wear particles like this are considered sludge; if left in the fluid, they prematurely wear on system components and degrade fluid viscosity.

Kenworth Truck 17 Years of Engine Protection

The challenge was to capture wear contamination missed by the trucks existing filtration system to prevent it from prematurely wearing on engine components. The main sources of engine oil contamination are air ingression, engine parts manufacturing, inherent wear particles in new oil, and break-in wear.

The 1000+ Hour Oil Change Interval Challenge

The transportation industry is looking for methods to safely extend maintenance periods to keep trucks on the road, which is good for business. The costs of fuel, new trucks and parts are always going up. Land star, a major transport provider with 8,000 transport units, relies on innovative technology to successfully compete in today’s tough transportation market. Al Jordan, a BCO and chief tester of new technology for Landstar, was asked to run the ADD-Vantage 9000 lube oil and fuel filters on his own C-15 Caterpillar engine for a year.

Transport Truck 10,000 km Oil Change Intervals

In 2006, Rob Bekker purchased a used Kenworth semi-truck with a CAT 3406 engine with 70,000 km runtime. Running up to 11 hours a day, with extended idle times throughout the winter, the truck needed a filter that would allow Bekker to maintain a 10,000 km oil change interval.

Transmasivo Public Transport Bus Engine Oil

Transmasivo, through the use of bio-fuels, was trying to reduce their emissions and wanted a filtration medium that would do the same while working efficiently on their bus line. Traditional filtration is incapable of removing contamination below 10 microns which causes damage to the fuel and oil system components, impedes the burn of the fuel, and increases emissions.

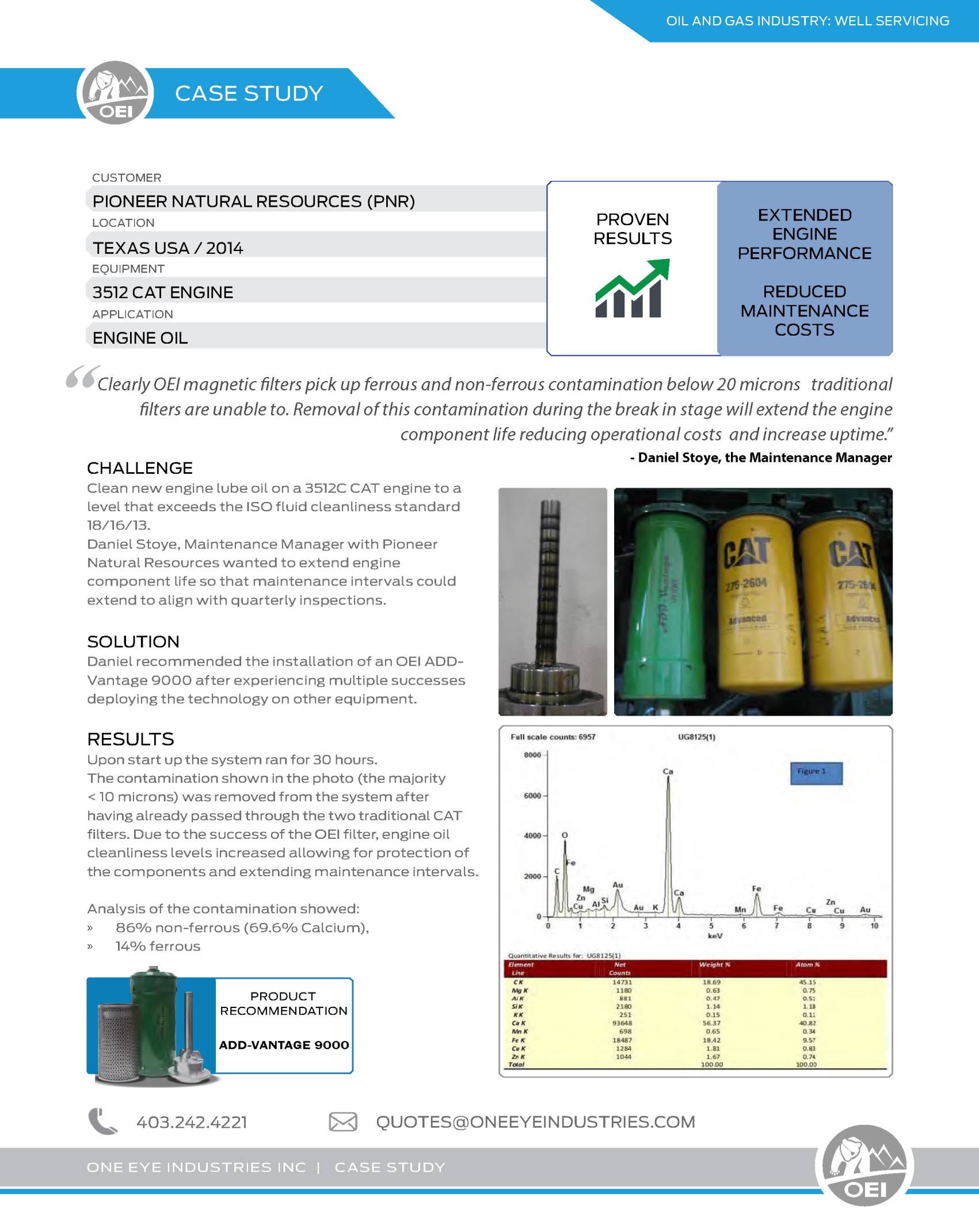

Pioneer 3512 CAT Engine Oil

The challenge was to clean new engine lube oil on a 3512C CAT engine to a level that exceeds the ISO fluid cleanliness standard 18/16/13, and to extend engine component life so that maintenance intervals could extend to align with quarterly inspections.

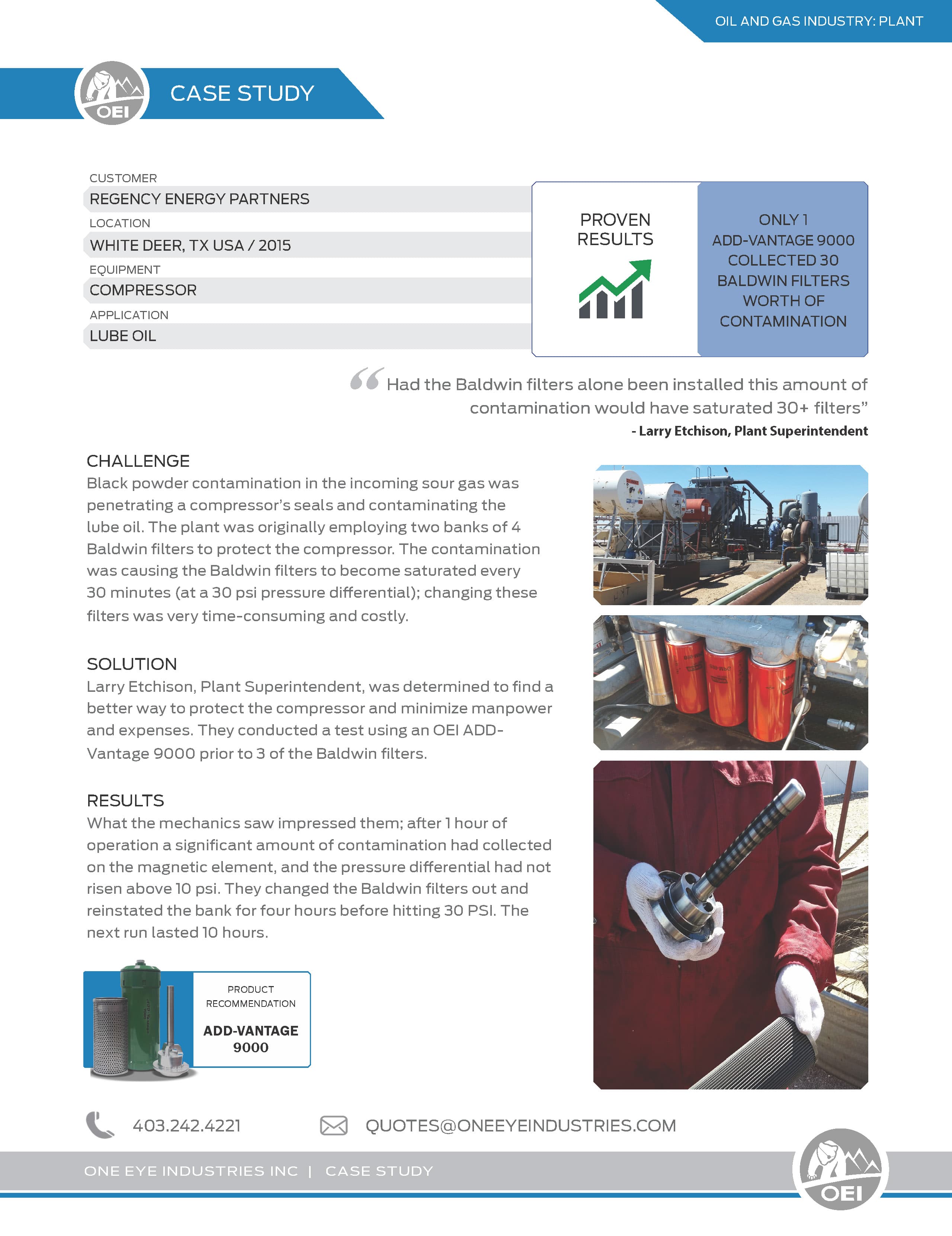

Regency Energy Partners Compressor Lube Oil

Black powder contamination in the incoming sour gas was penetrating a compressor’s seals and contaminating the lube oil. The plant was originally employing two banks of 4 Baldwin filters to protect the compressor. The contamination was causing the Baldwin filters to become saturated every 30 minutes (at a 30 psi pressure differential). Changing these filters was very time-consuming and costly.

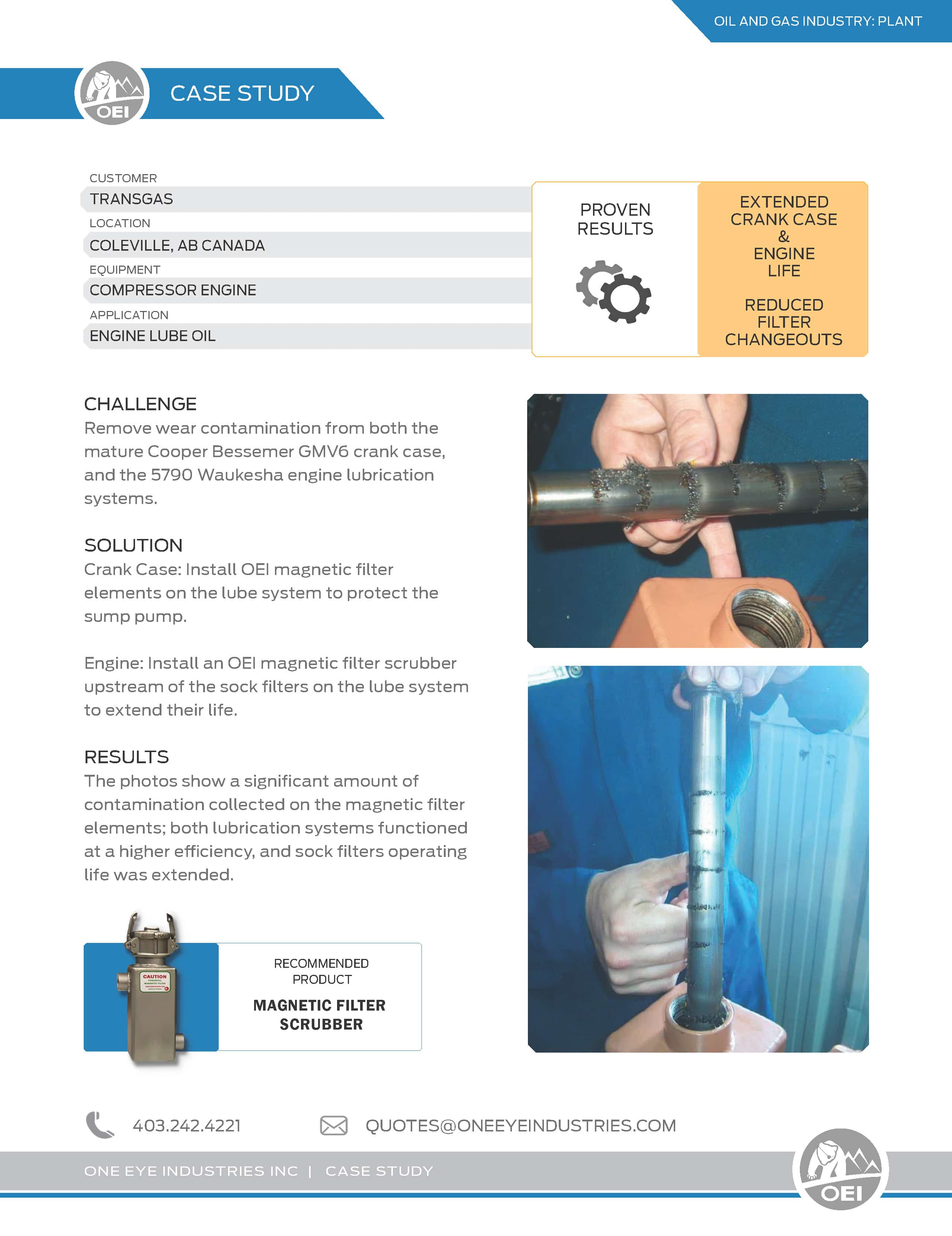

Transgas Crank Case & Engine Lube Oil

The challenge was to remove wear contamination from both the mature Cooper Bessemer GMV6 crank case, and the 5790 Waukesha engine lubrication systems.

Targa Resources Compressor Lube Oil Filtration Saves 300k Annually

The challenge was to remove black powder contamination at Targa’s Galena Park temrinal in purity NGL products and loading, vapor handling and facility lubrication systems.

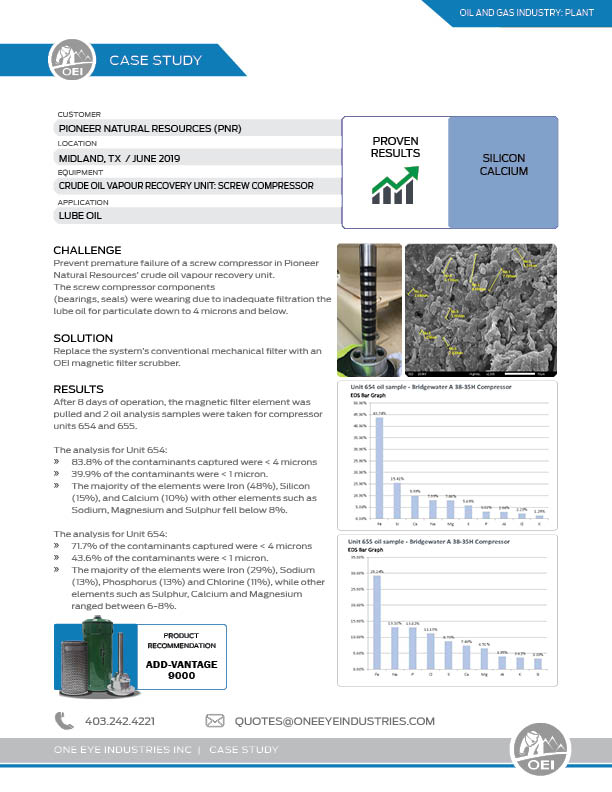

Screw Compressor Lube Oil Analysis

The challenge was to prevent premature failure of a screw compressor in Pioneer Natural Resources’ crude oil vapour recovery unit. The screw compressor components (bearings, seals) were wearing due to inadequate filtration the lube oil for particulate down to 4 microns and below.

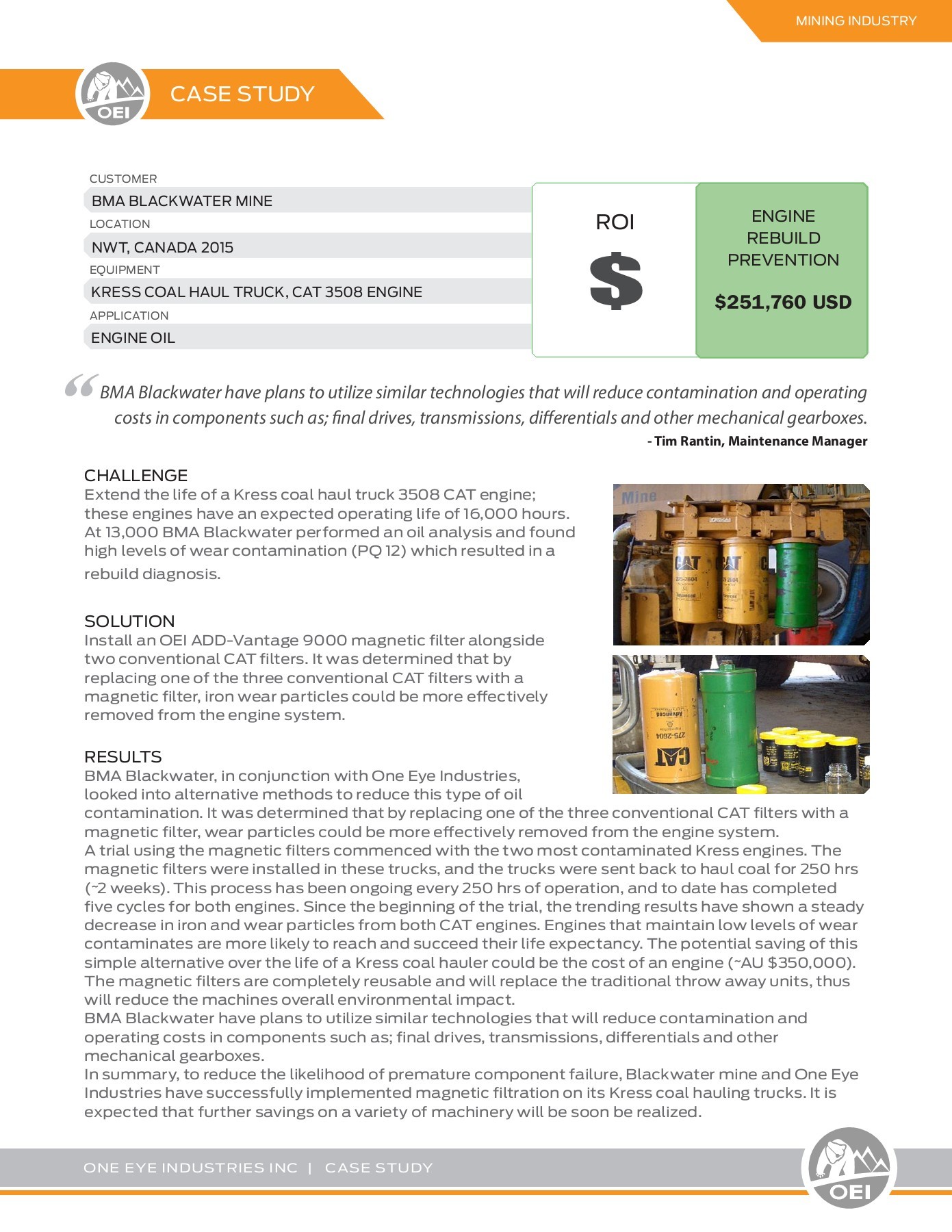

Cancelling the Rebuild of a CAT 3508 Haul Truck Engine

The challenge was to extend the life of a Kress coal haul truck 3508 CAT engine; these engines have an expected operating life of 16,000 hours. At 13,000 BMA Blackwater performed an oil analysis and found high levels of wear contamination (PQ 12) which resulted in a rebuild diagnosis.

36 Haul Truck Engines & 1.5 Million Dollar Savings

The challenge was to extend engine oil change interval and rebuild times. The CAT 785D haul trucks at a gold mine were experiencing frequent engine failures due to wear contamination. The mine required a solution for equipment downtime and lost productivity.

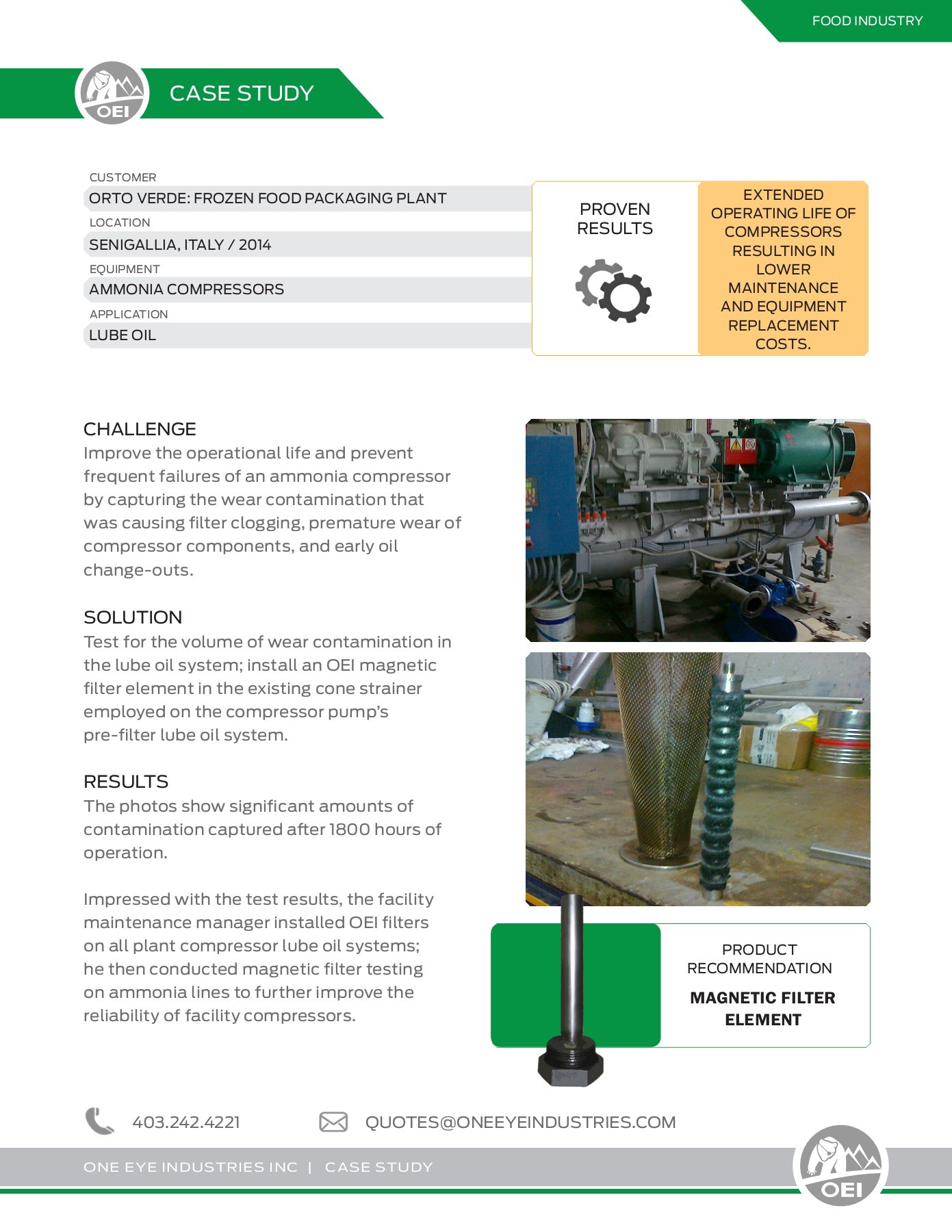

Orto Verde Ammonia Compressor Lube Oil

The challenge was to improve the operational life and prevent frequent failures of an ammonia compressor by capturing the wear contamination that was causing filter clogging, premature wear of compressor components, and early oil change-outs.

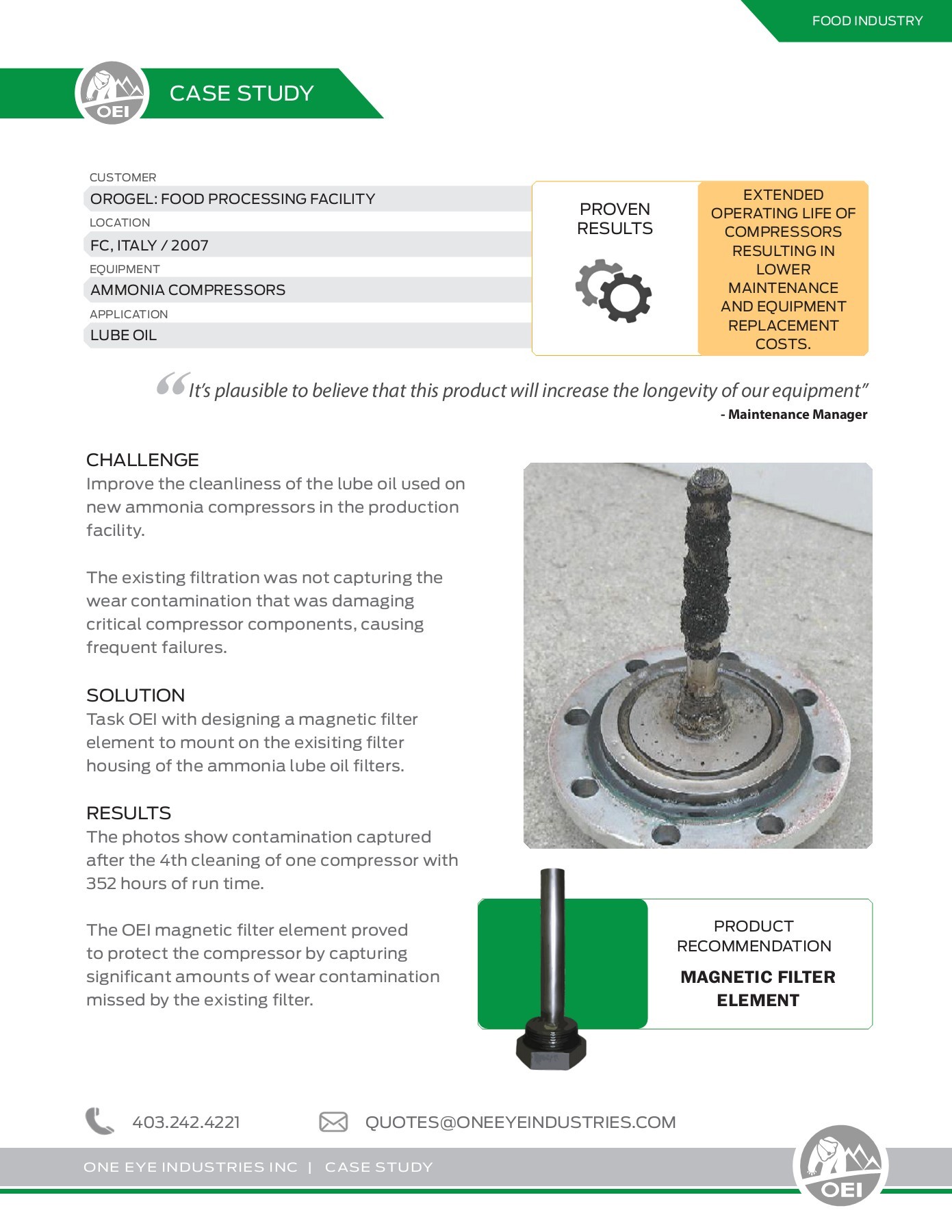

Orogel Ammonia Compressor Lube Oil

The challenge was to improve the cleanliness of the lube oil used on new ammonia compressors in the production facility. The existing filtration was not capturing the wear contamination that was damaging critical compressor components, causing frequent failures.

Mexican Navy Engine Oil

The challenge was to capture wear contamination missed by the naval ship’s existing filtration system and prevent it from prematurely wearing engine components such as bearings. The source of the contamination is air ingression, engine parts manufacturing, inherent wear particles in new oil, and break-in operating.

OEI magnetic filters are designed for 95+% efficiency: they are optimized for fluid viscosity, flow volume, flow rate, temperature, mobility, and mounting requirements.

Use of the OEI Data Form will provide the necessary specifications for OEI to determine which product is right for you

REQUEST A QUOTE

4344 12th Street SE Calgary,

AB T2G 3H9 Canada

(403) 242 4221

quotes@oneeyeindustries.com