Gearboxes

Put an end to wear contamination that causes 80% of your equipment failures. Prevent the degradation of gearbox components that leads to catastrophic system failure.

North Sea Offshore Wind Turbine Gearbox

Wind turbine gearboxes are susceptible to failure well before their designed service lives because 1) wind turbines consist of a dozen bearings that work simultaneously for years, and 2) the variability of wind patterns leads to fluctuating loads on wind turbine components. These failures are a major cause of downtime, unplanned maintenance, and parts replacement; they are the primary cause of increased opex for energy operators, and higher utility bills for customers.

Haul Truck Front Wheel Hub Roller Bearings

The mine site was experiencing premature outer taper roller bearing failures on the front wheel hubs of their Komatsu 860 E and 960 E haul trucks.

The site operates 92 haul trucks, and the expected operating life of front wheel hubs is 20 000 hours; the site however, was experiencing 1-3 failures per week at a cost of 1 million South African Rand per failure.

The mine started investigating in May of 2015. Oil analysis determined that during operation, contamination was wearing heavily on the outer taper roller bearings which was, in turn, causing premature wheel hub failure.

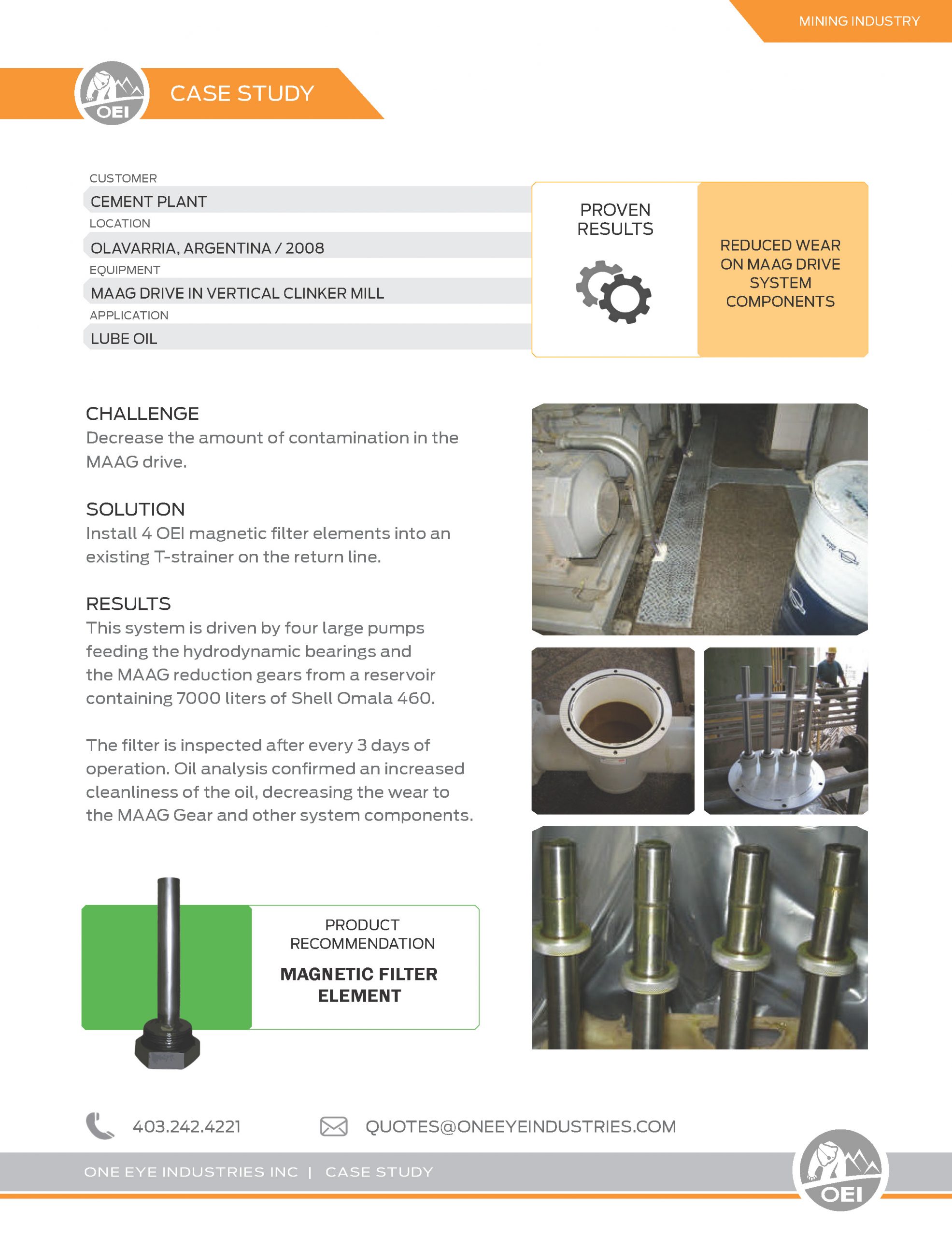

Argentina Cement Plant Maag Drive

The challenge was to decrease the amount pf contamination in the MAAG drive. As a solution, the customer installed 4 OEI magnetic filter elements into an existing T-strainer on the return line.

Dragline Gearbox Testimonials

The challenge was to lower the ferrous contamination levels in dragline #5 gearboxes, and improve ISO fluid cleanliness levels.

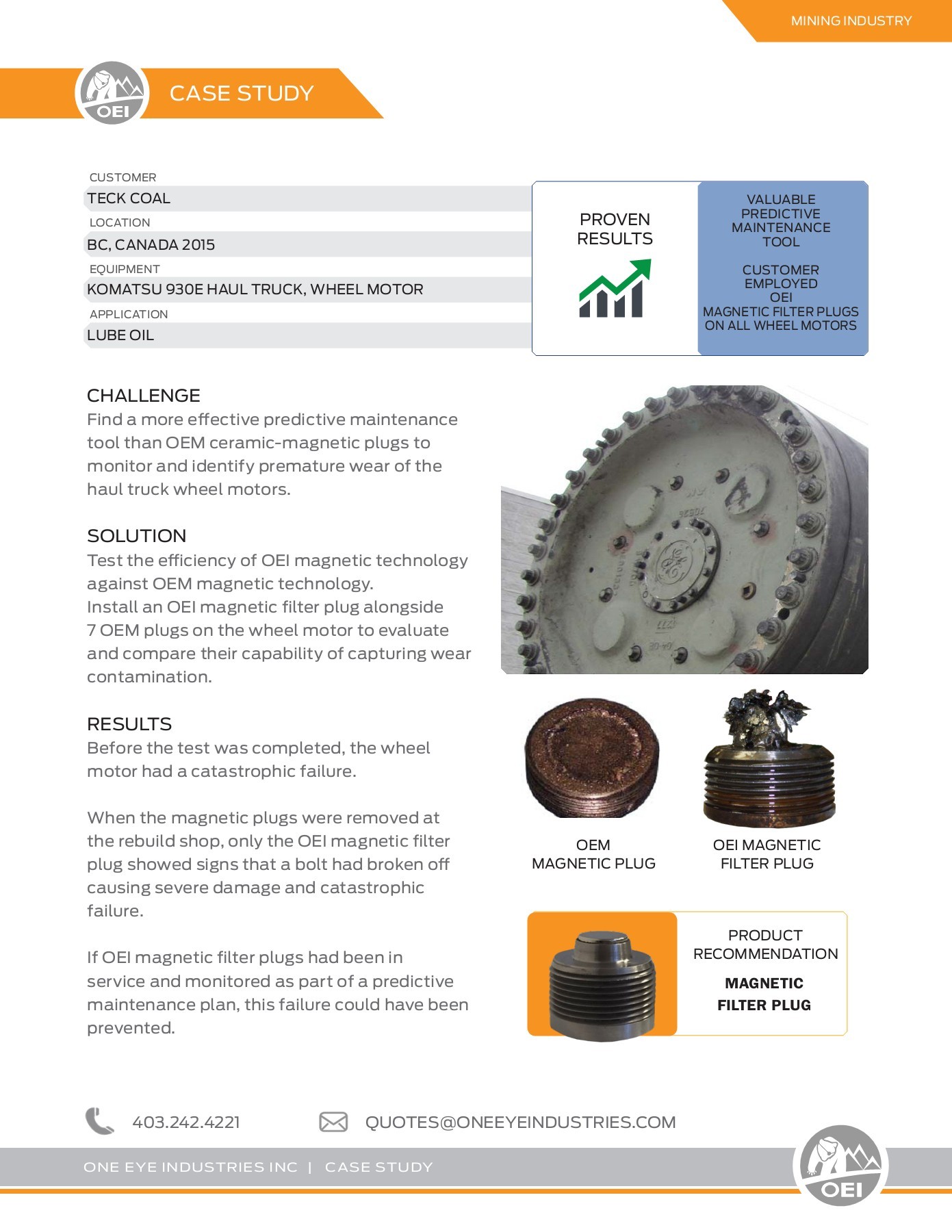

Predictive Maintenance on a 930E Haul Truck Wheel Motor

The challenge was to find a more effective predictive maintenance tool than OEM ceramic-magnetic plugs to monitor and identify premature wear of the haul truck wheel motors.

Prevent Final Drive Failure fo a C10 & C11 Dozer Fleet

A leading coal producer in Australia’s Bowen basin wanted to extend the service intervals of their dozer fleet from 250 hours to 330 hours. The OEM CAT magnetic filter plugs were unable to remove enough wear contamination from the dozer’s final drives to protect them from premature failure, and the mine required a more effective magnetic technology. If the service extension could be achieved, the cost savings would be significant in terms of reducing transport (float hire), unscheduled downtime, equipment replacement, and maintenance.

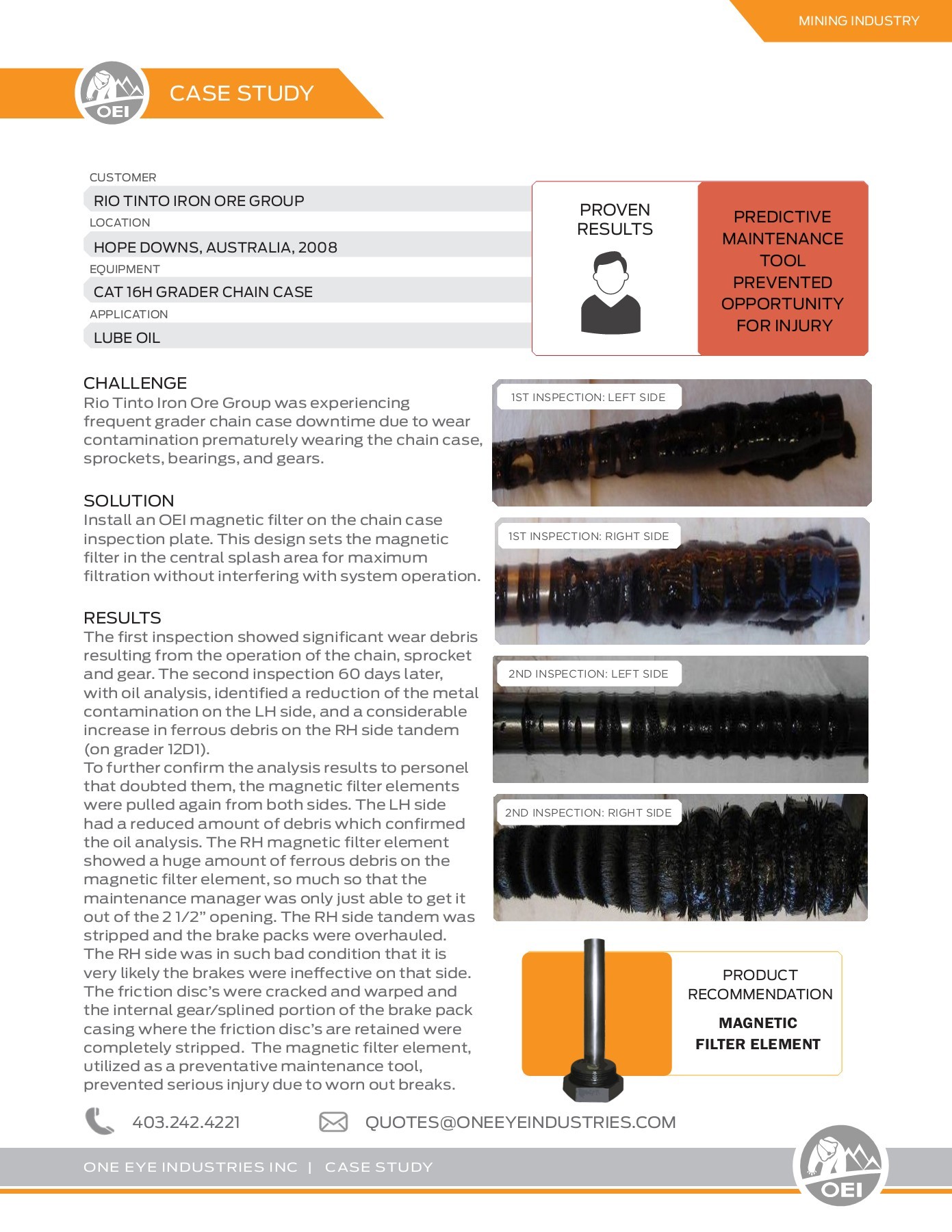

Preventing Break Failure on a 16H Grader

Rio Tinto Iron Ore Group was experiencing frequent grader chain case downtime due to wear contamination prematurely wearing the chain case, sprockets, bearings, and gears.

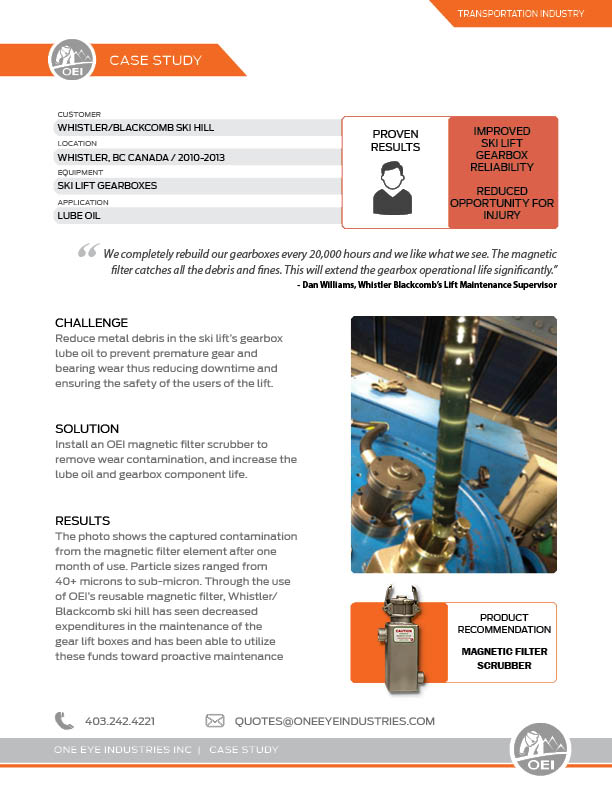

Improving Ski Lift Gearbox Reliability

The challenge was to reduce metal debris in the ski lift’s gearbox lube oil to prevent premature gear and bearing wear thus reducing downtime and ensuring the safety of the users of the lift.

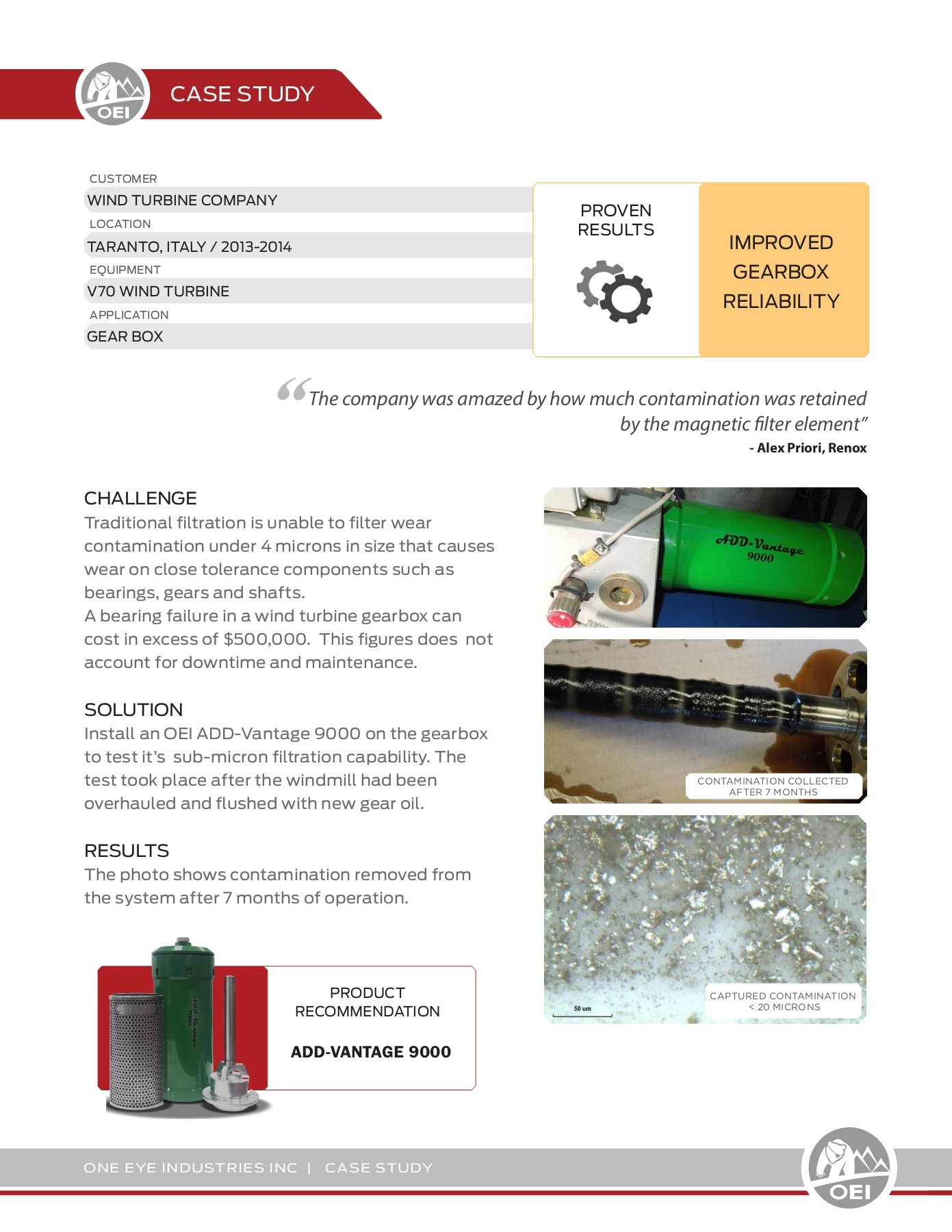

Improving Wind Turbine Reliability

Traditional filtration is unable to filter wear contamination under 4 microns in size that causes wear on close tolerance components such as bearings, gears and shafts. A bearing failure in a wind turbine gearbox can cost in excess of $500,000. This figures does not account for downtime and maintenance.

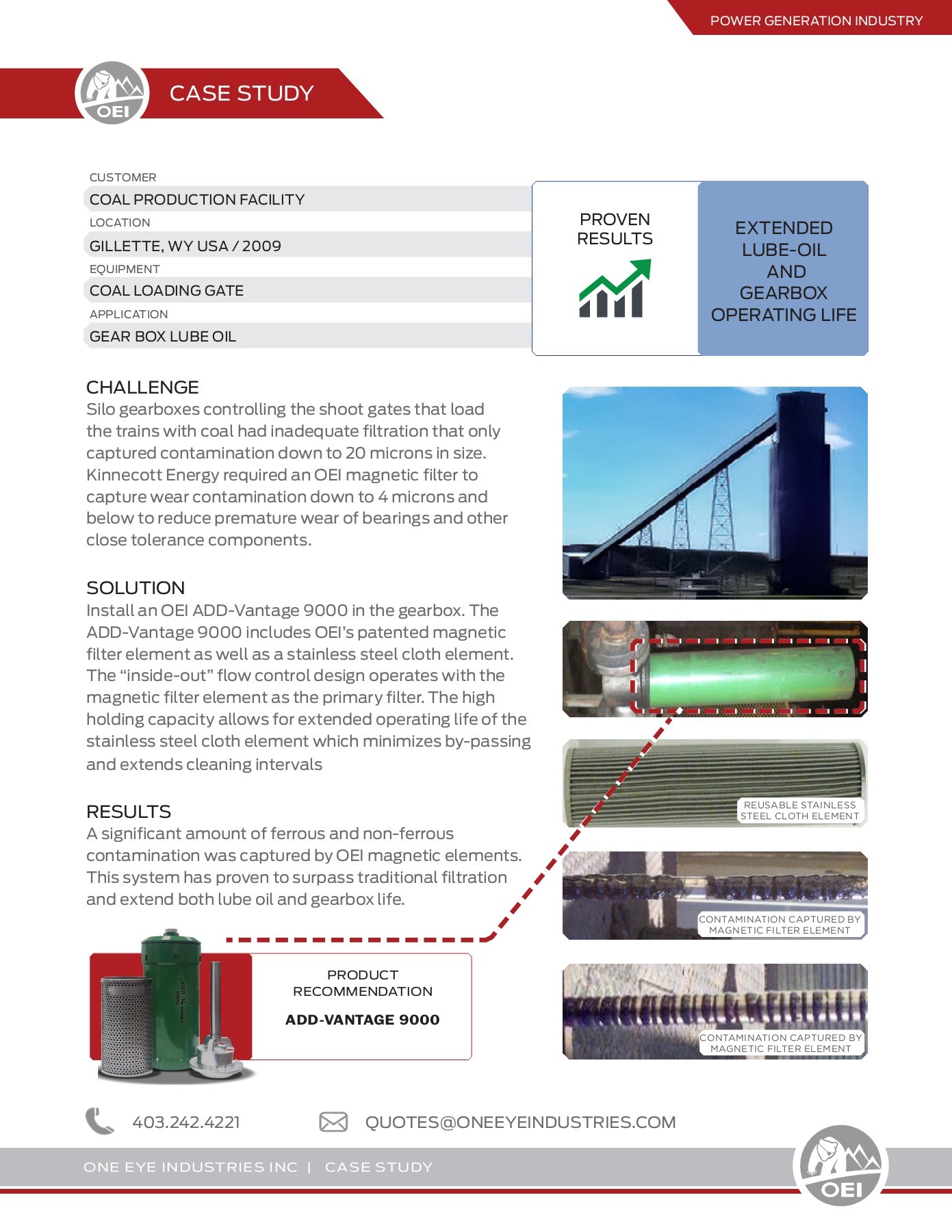

Coal Loading Gate Gearbox Protection

Silo gearboxes controlling the shoot gates that load the trains with coal had inadequate filtration that only captured contamination down to 20 microns in size. Kinnecott Energy required an OEI magnetic filter to capture wear contamination down to 4 microns and below to reduce premature wear of bearings and other close tolerance components.

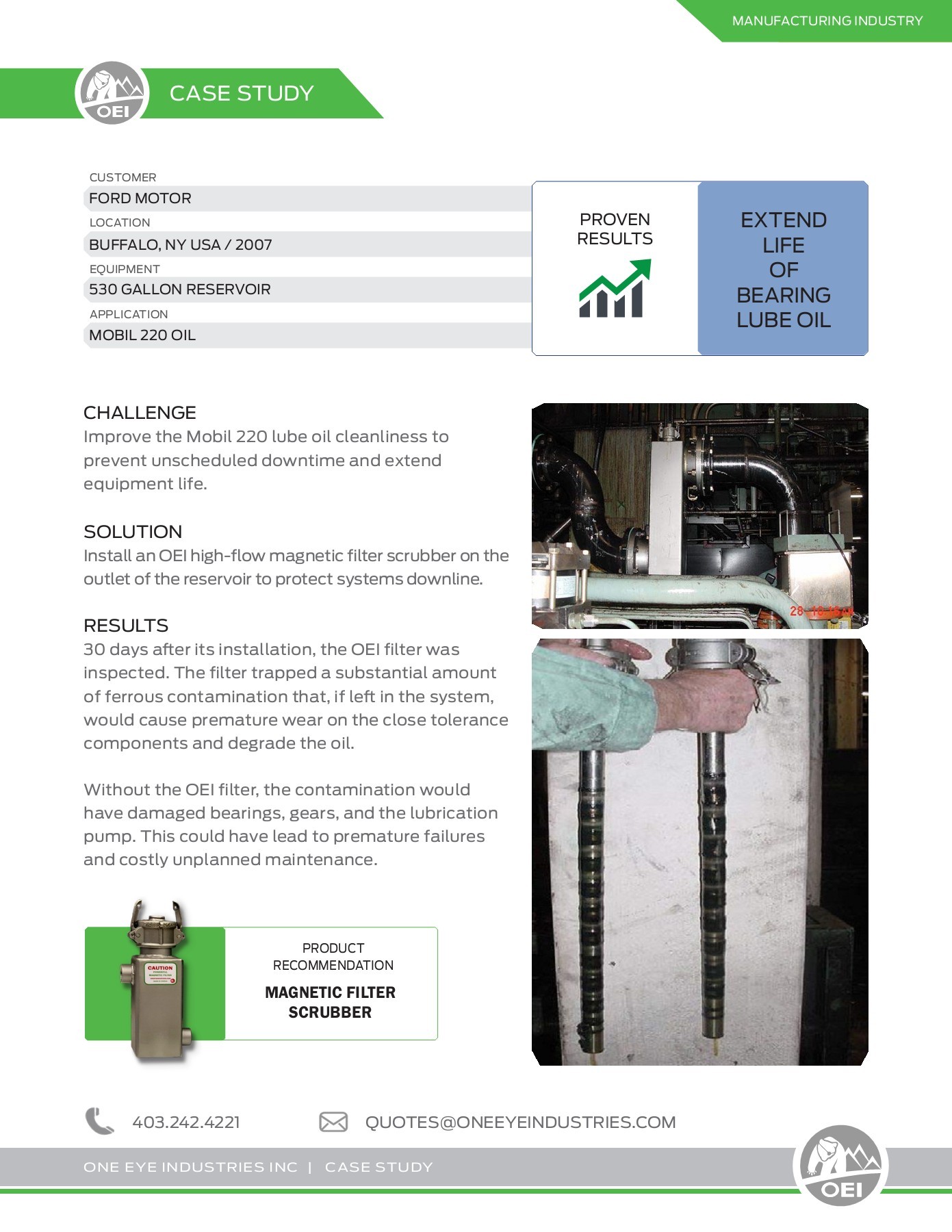

Lube Oil Reservoir Filtration

The challenge was to improve the Mobil 220 lube oil cleanliness to prevent unscheduled downtime and extend equipment life.

OEI magnetic filters are designed for 95+% efficiency: they are optimized for fluid viscosity, flow volume, flow rate, temperature, mobility, and mounting requirements.

Use of the OEI Data Form will provide the necessary specifications for OEI to determine which product is right for you

REQUEST A QUOTE

4344 12th Street SE Calgary,

AB T2G 3H9 Canada

(403) 242 4221

quotes@oneeyeindustries.com