Process Water Treatment

It is critical to protect utility and process water from rust and corrosion contamination. Common applications are cooling lines, boiler feed lines, reservoirs, and process water lines. These applications require quality filtration of hard particles (iron, silica, sodium, and others) under 5 microns to protect their tight tolerance components from wear and eventual failure. Poor water quality directly results in increased maintenance and downtime.

Featured Case Study

Proven Result:

Successful Test

0% Iron Found in Municipal Water with OEI Filtration

Customer

Kazakhstan Center for Modernization and Development of Housing and Public Utilities

Location

Aktau, Kazakhstan / 2019

Equipment

Boiler System

Application

Boiler Water, Drinking Water, Process Water

Challenge

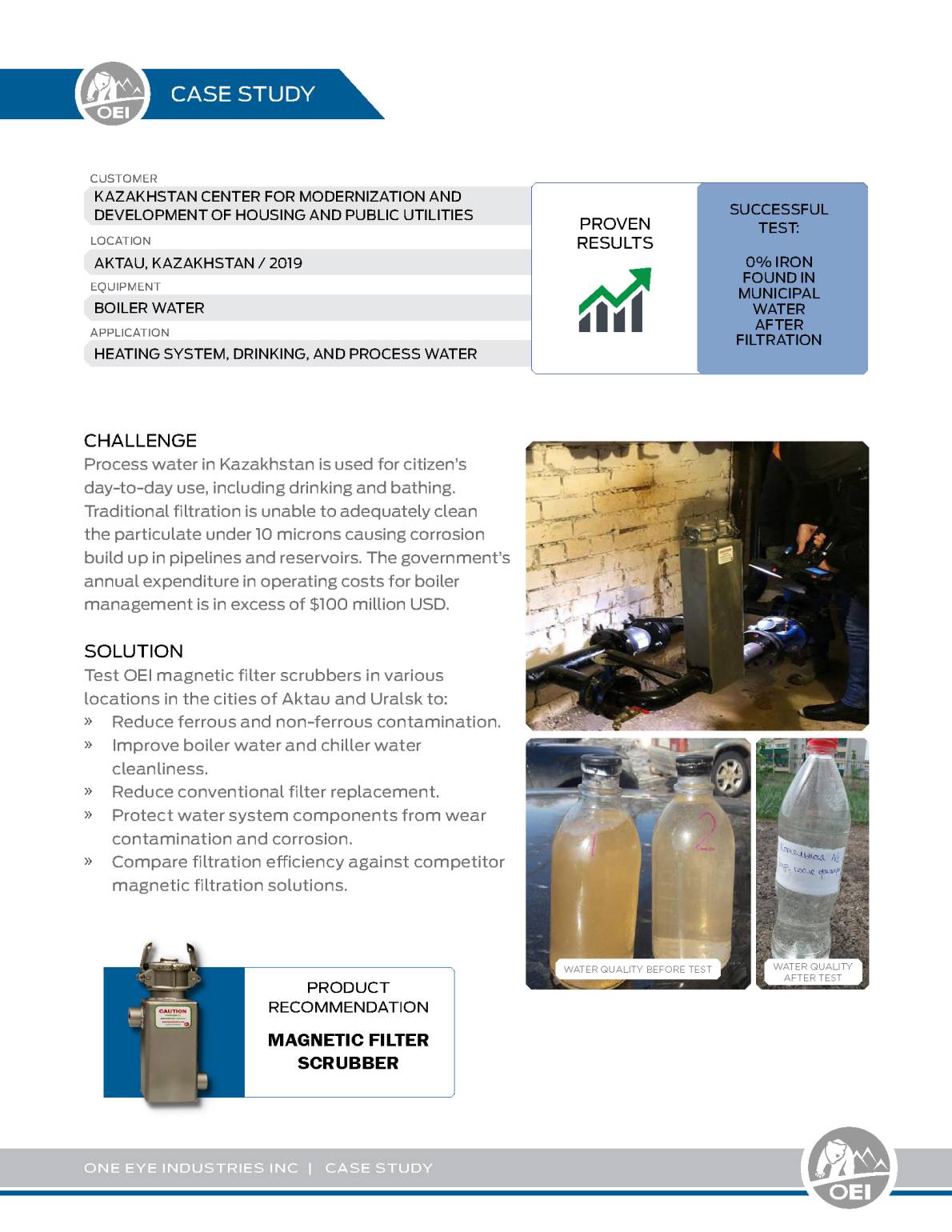

Process water in Kazakhstan is used for citizen’s day-to-day use, including drinking and bathing. Traditional filtration is unable to adequately clean the particulate under 10 microns causing corrosion build up in pipelines and reservoirs. The government’s annual expenditure in operating costs for boiler management is in excess of $100 million USD.

Solution

Test OEI magnetic filter scrubbers in various locations in the cities of Aktau and Uralsk to:

- Reduce ferrous and non-ferrous contamination.

- Improve boiler water and chiller water cleanliness.

Reduce conventional filter replacement. - Protect water system components from wear contamination and corrosion.

- Compare filtration efficiency against competitor magnetic filtration solutions.

Results

The magnetic filters collected significant amounts of contamination that were for testing; analysis results demonstrated a dramatic decrease of iron, magnesium and other harmful elements.

The government of Kazakhstan is planning to install OEI magnetic filters statewide on major water infrastructure including pipelines, buildings, and other locations.

Water Treatment

CASE STUDIES

Improved Water Quality for Boiler Protection

Improve water quality to limit damage to facility systems and reduce process water contaminants. High volumes of iron oxide, resulting from piping corrosion, enter the boiler system and water supply line; the rust contamination continues downstream, degrading process water quality and damaging facility systems.

Kazakhstan Municipal Water Quality Test

Process water in Kazakhstan is used for citizen’s day-to-day use, including drinking and bathing. Traditional filtration is unable to adequately clean the particulate under 10 microns causing corrosion build up in pipelines and reservoirs. The government’s annual expenditure in operating costs for boiler management is in excess of $100 million USD.

Hot Rolling Mill Coolant Flush Water

Contamination in the centrifuge system was causing mechanical seal failure. The coolant flush water required a more effective filtration system than the system’s conventional filter to remove contamination down 4 microns and below.

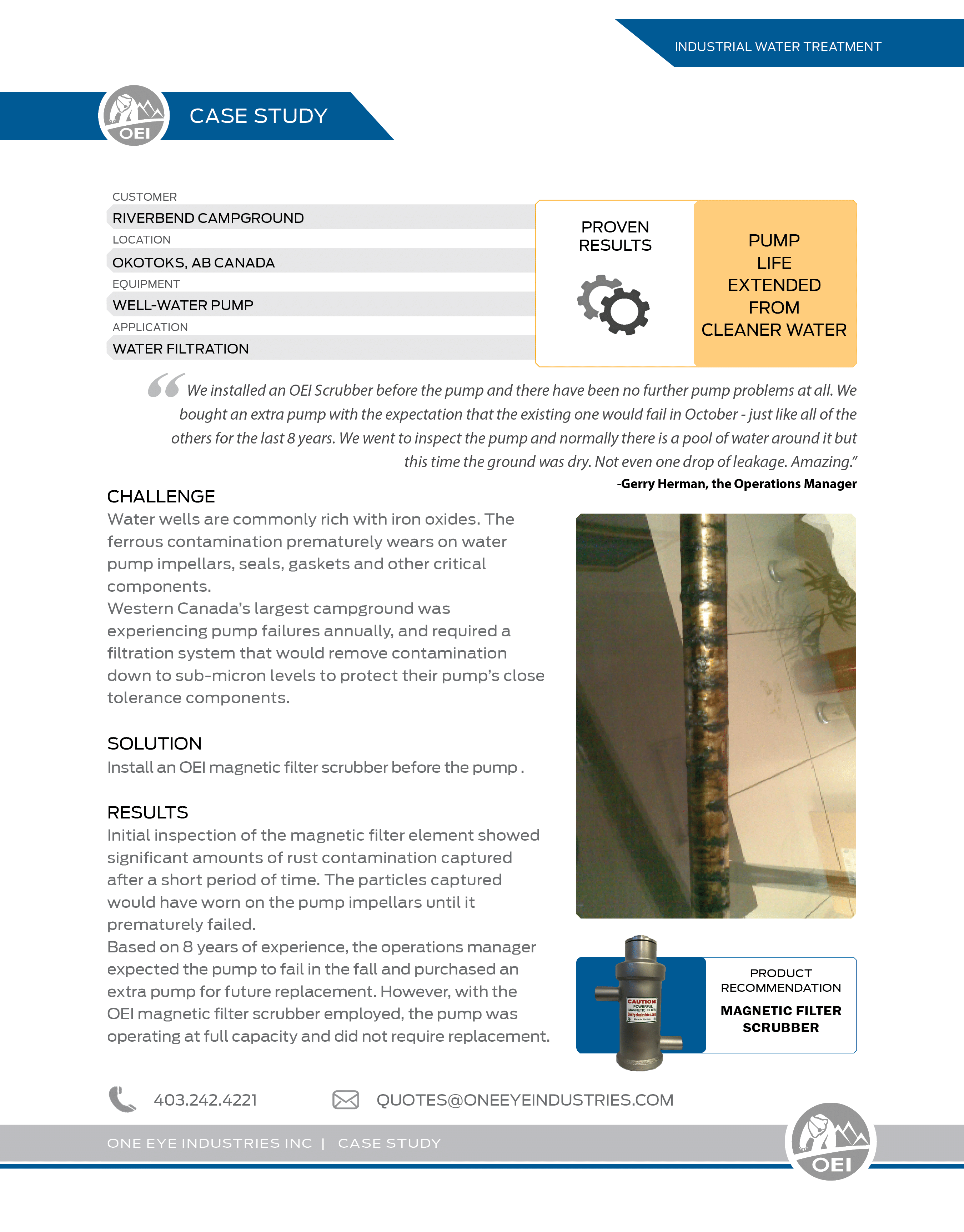

Campground Water Pump Protection

Water wells are commonly rich with iron oxides. The ferrous contamination prematurely wears on water pump impellars, seals, gaskets and other critical components. Western Canada’s largest campground was experiencing pump failures annually, and required a filtration system that would remove contamination down to sub-micron levels to protect their pump’s close tolerance components.

OEI magnetic filters are designed for 95+% efficiency: they are optimized for fluid viscosity, flow volume, flow rate, temperature, mobility, and mounting requirements.

Use of the OEI Data Form will provide the necessary specifications for OEI to determine which product is right for you

REQUEST A QUOTE

4344 12th Street SE Calgary,

AB T2G 3H9 Canada

(403) 242 4221

quotes@oneeyeindustries.com