Hydraulics

Protect your hydraulic equipment from fluid degradation. Sub-micron filtration is critical to protect valves and bearings which ensures your hydraulic systems perform to expectations.

Ocean Edge Services Subsea HPU Hydraulic Fluid

Inadequate filtration was allowing wear contamination under 4 microns to degrade the water-based-glycol hydraulic fluid that is used to operate Ocean Edge’s subsea HPU. This contamination damages the DC valves which have tolerances below 1 micron. In these systems, if any contamination is present, the effects can cost millions of dollars to resurface the HPU for repairs.

A cleanliness level of 6 NAS is the standard for subsea control systems. When conducting fluid treatment, traditional filtration takes 10 to 12 hours to achieve a NAS 6 and that still leaves the system vulnerable to valve failure.

Nabors Drilling HPU Hydraulic Fluid

The tolerances of hydraulic systems are 4 micron to sub-micron, and traditional filtration is unable to remove this contamination to these levels.

Once a month, a large filter truck is hired to filter the hydraulic fluid from the HPU for a 16 hour interval. This filtration is costly and unable to remove wear particles under 4 microns that cause hydraulic valve failures.

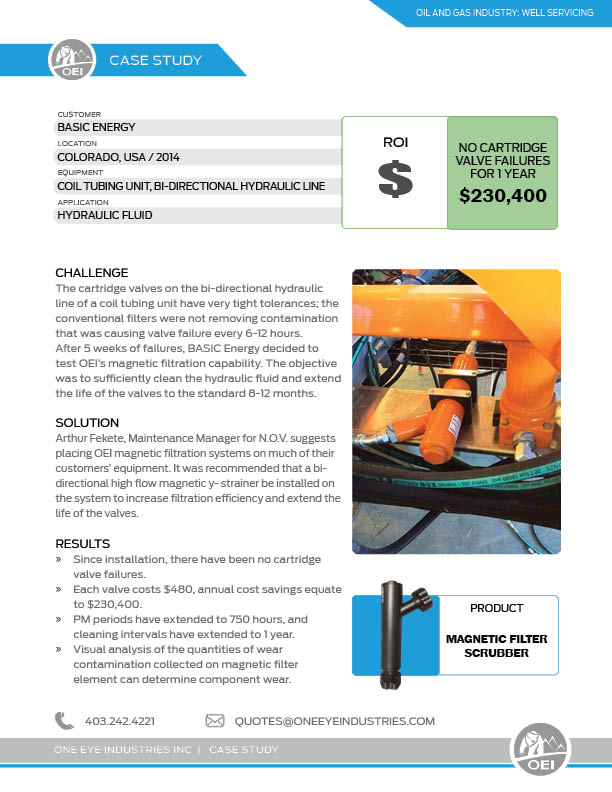

Basic Energy Bi-directional Hydraulic Fluid Line

The cartridge valves on the bi-directional hydraulic line of a coil tubing unit have very tight tolerances; the conventional filters were not removing contamination that was causing valve failure every 6-12 hours. After 5 weeks of failures, BASIC Energy decided to test OEI’s magnetic filtration capability. The objective was to sufficiently clean the hydraulic fluid and extend the life of the valves to the standard 8-12 months.

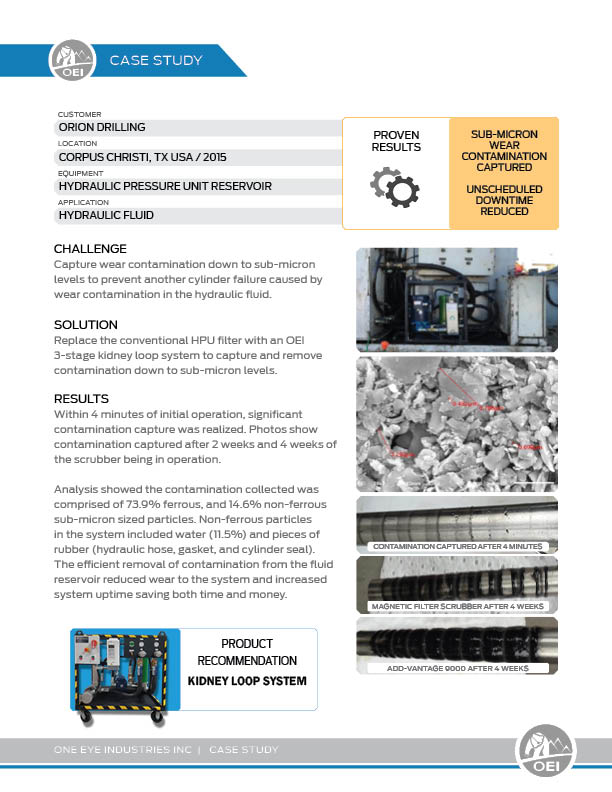

Orion HPU Hydraulic Fluid

The challenge was to capture wear contamination down to sub-micron levels to prevent another cylinder failure caused by wear contamination in the hydraulic fluid.

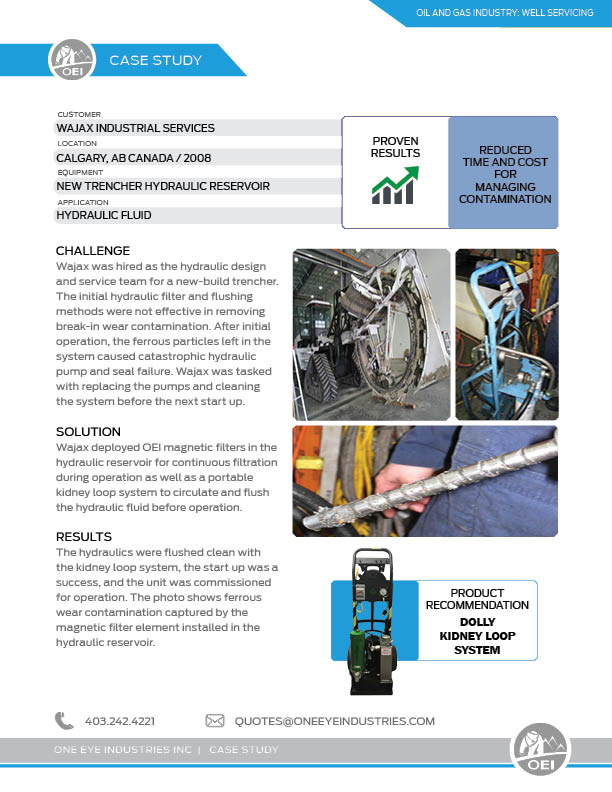

Wajax Trencher Hydraulic Fluid Reservoir

Wajax was hired as the hydraulic design and service team for a new-build trencher. The initial hydraulic filter and flushing methods were not effective in removing break-in wear contamination. After initial operation, the ferrous particles left in the system caused catastrophic hydraulic pump and seal failure. Wajax was tasked with replacing the pumps and cleaning the system before the next start up.

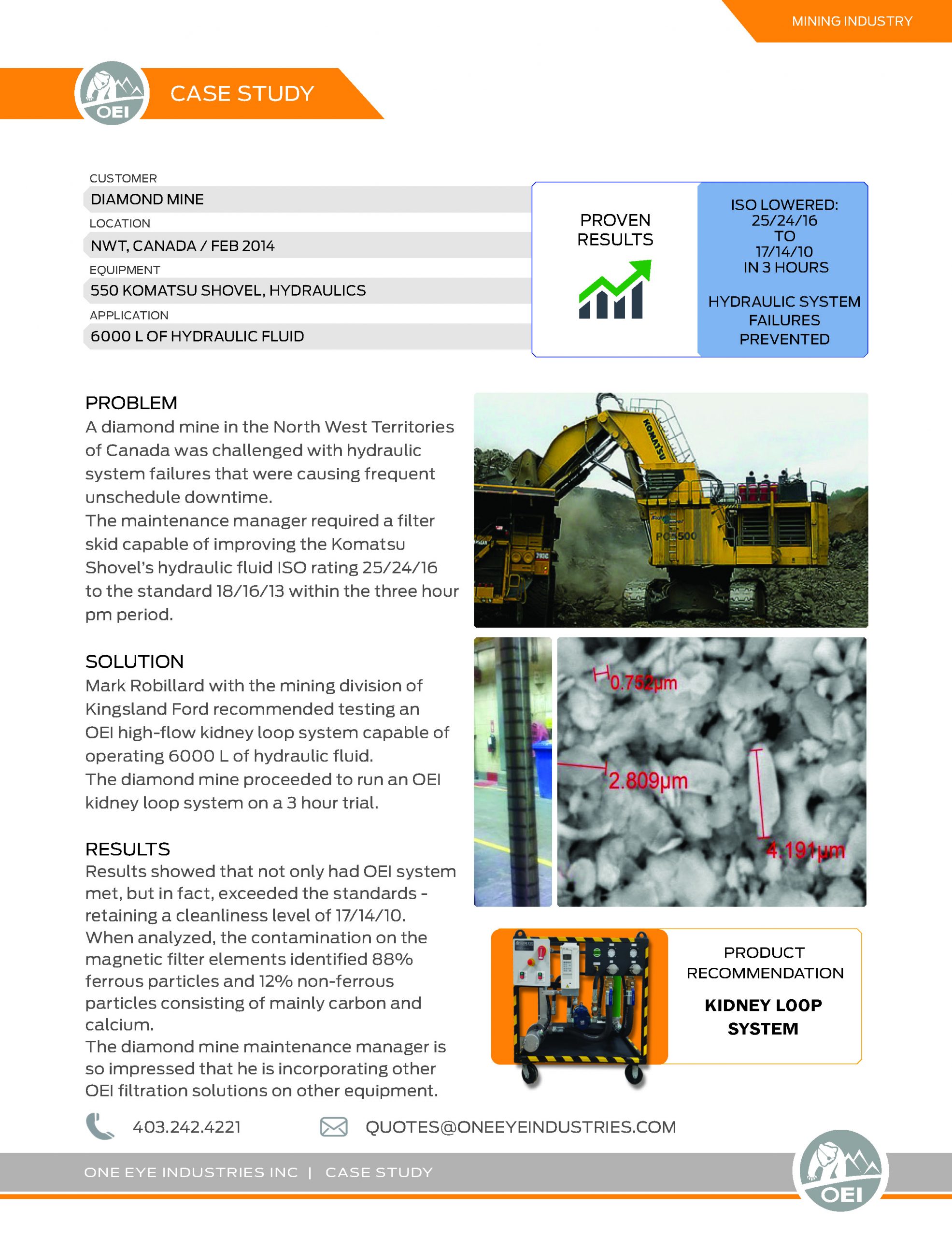

Diamond Mine Shovel Hydraulic Fluid

A diamond mine in the North West Territories of Canada was challenged with hydraulic system failures that were causing frequent unschedule downtime. The maintenance manager required a filter skid capable of improving the Komatsu Shovel’s hydraulic fluid ISO rating 25/24/16 to the standard 18/16/13 within the three hour pm period.

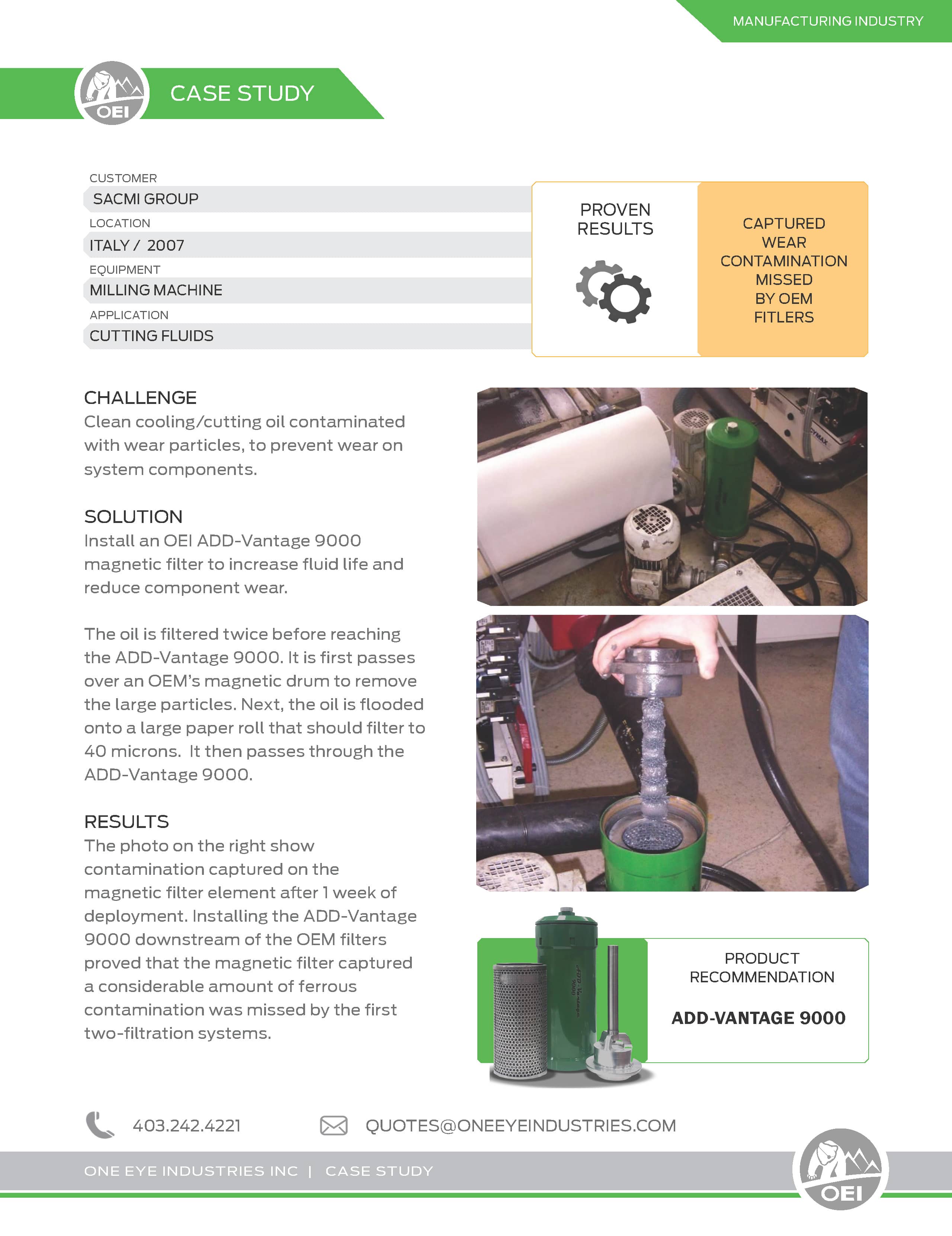

Improving SACMIs Cooling Cutting Fluid with Quality Filtration

The challenge was to clean cooling/cutting oil contaminated with wear particles, to prevent wear on system components.

Precision Drilling Top Drive Closed Loop Hydraulics

As this is a closed loop system flowing 300 gpm from their pump to the motor and vice versa, Precision Drilling needed a filter that was capable of filtering bidirectionally. The conventional filters in place between the pump and motor was unable to protect against particulate under 10 microns. The tolerances of the pump and motor components are < 4 microns. Further, they required filtration for the fluid before the pump to protect against contamination produced by the motor.

OEI magnetic filters are designed for 95+% efficiency: they are optimized for fluid viscosity, flow volume, flow rate, temperature, mobility, and mounting requirements.

Use of the OEI Data Form will provide the necessary specifications for OEI to determine which product is right for you

REQUEST A QUOTE

4344 12th Street SE Calgary,

AB T2G 3H9 Canada

(403) 242 4221

quotes@oneeyeindustries.com