Water Systems

Protect utility and process water from rust and corrosion contamination. Common applications are cooling lines, boiler feed lines, reservoirs, and process water lines.

Hot Rolling Mill Coolant Flush Water

Contamination in the centrifuge system was causing mechanical seal failure. The coolant flush water required a more effective filtration system than the system’s conventional filter to remove contamination down 4 microns and below.

Improved Water Quality for Boiler Protection

Improve water quality to limit damage to facility systems and reduce process water contaminants. High volumes of iron oxide, resulting from piping corrosion, enter the boiler system and water supply line; the rust contamination continues downstream, degrading process water quality and damaging facility systems.

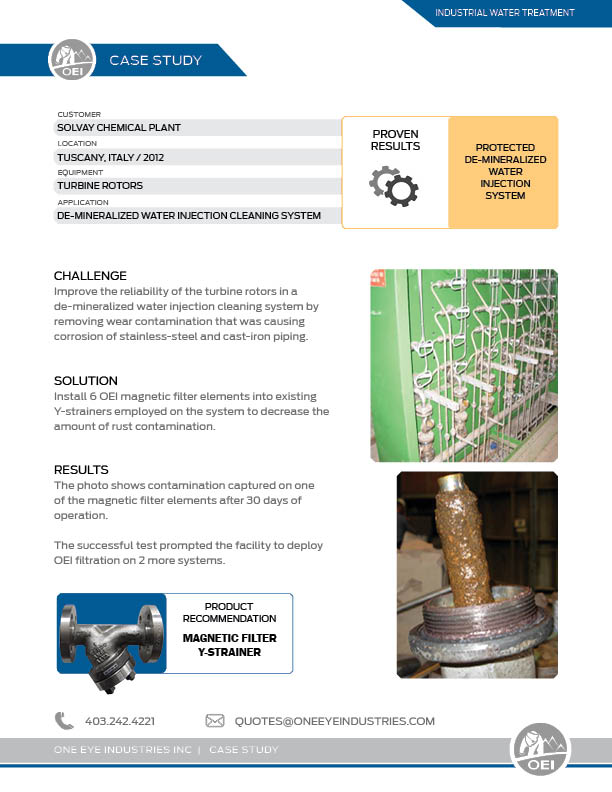

De-mineralized Water Injection System

Improve the reliability of the turbine rotors in a de-mineralized water injection cleaning system by removing wear contamination that was causing corrosion of stainless-steel and cast-iron piping.

Meeting Municipal Water Quality Standards

The challenge was to improve the quality of facility process water to meet municipal standards. This facility uses municipal water in the manufacturing of it’s gun powder. String filters were ineffective in removing the contamination caused by corrosion of the facilities’ carbon-steel piping and systems. The rust contamination resulted in the facility process water failing to meet municipal water quality standards.

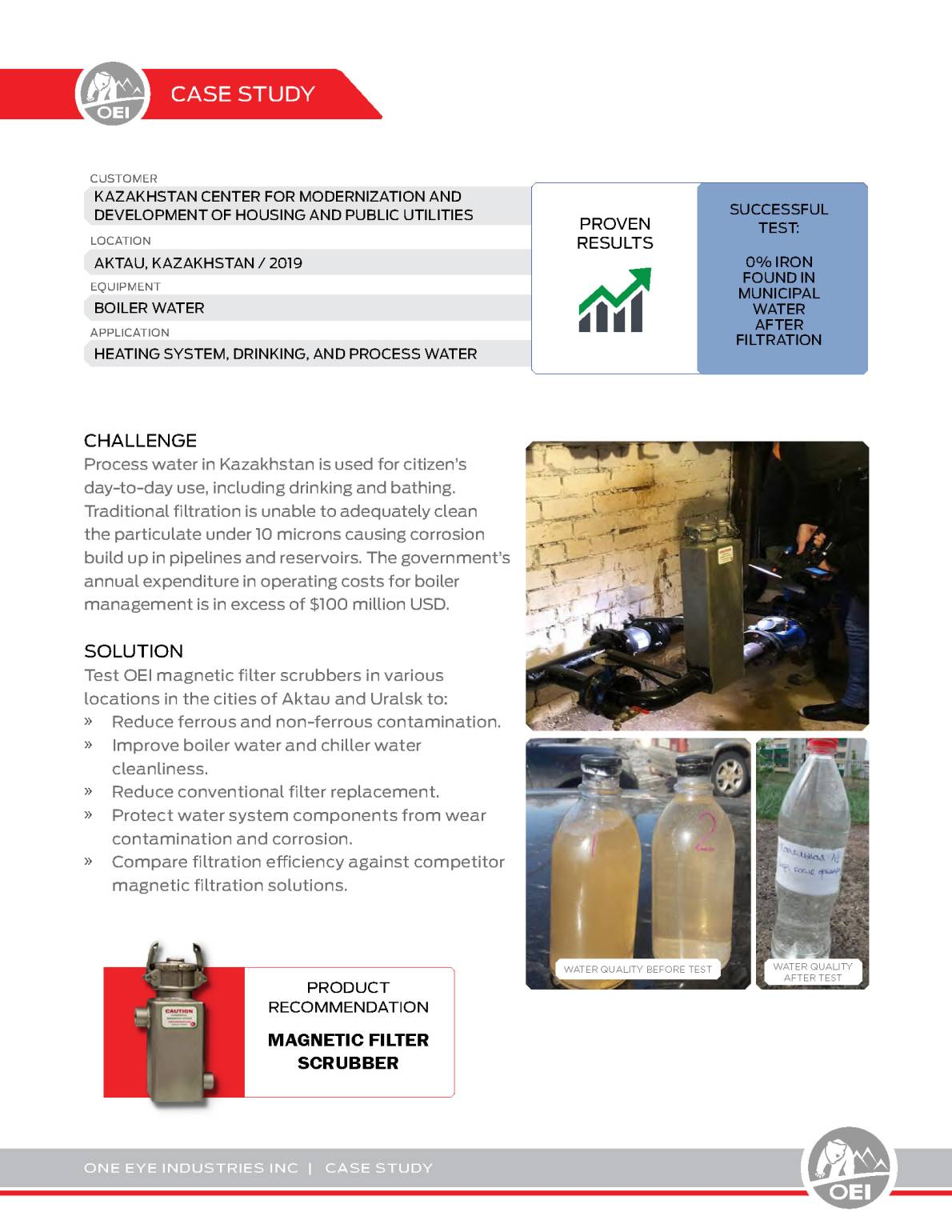

Kazakhstan Municipal Water Quality Test

Process water in Kazakhstan is used for citizen’s day-to-day use, including drinking and bathing. Traditional filtration is unable to adequately clean the particulate under 10 microns causing corrosion build up in pipelines and reservoirs. The government’s annual expenditure in operating costs for boiler management is in excess of $100 million USD.

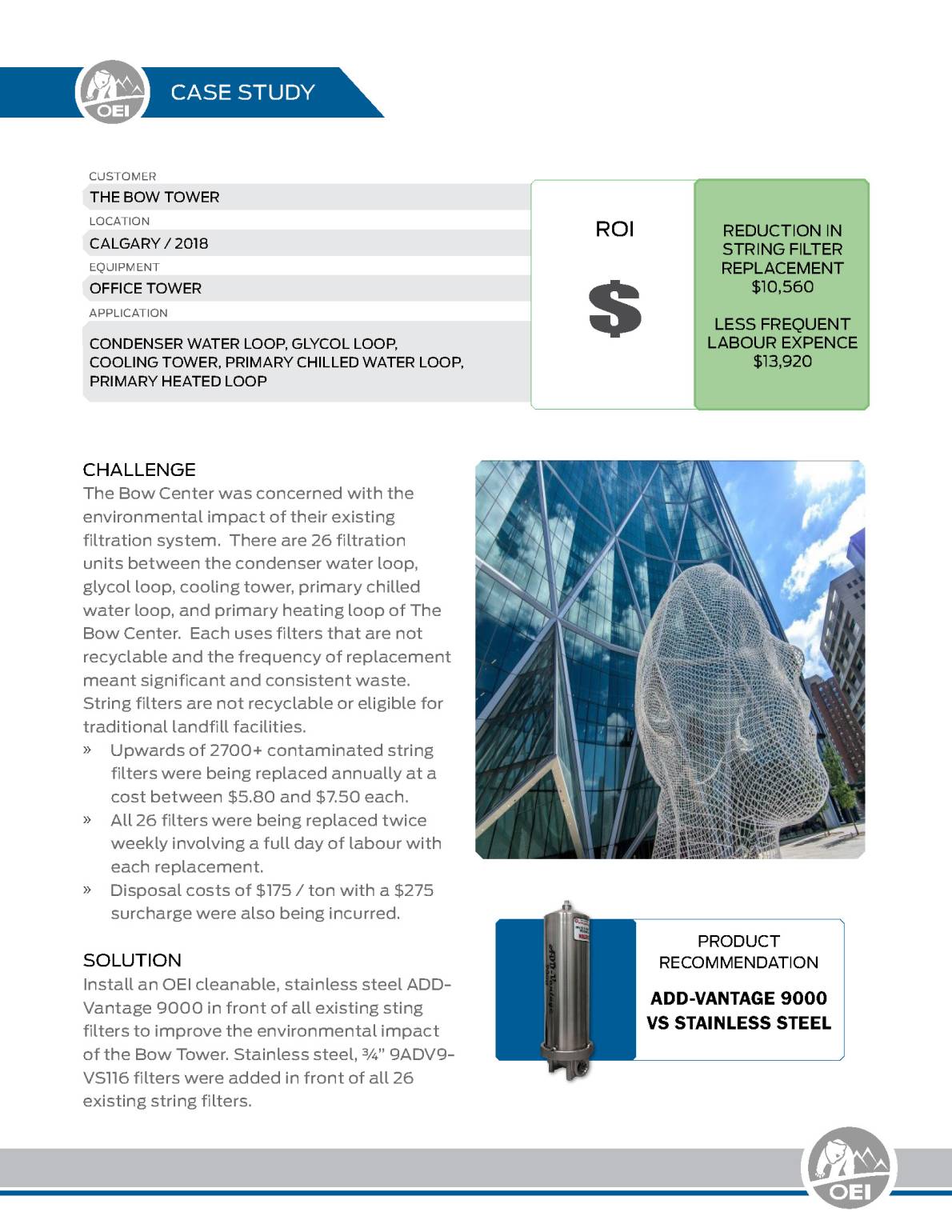

BOW Center HVAC Outfitting

The Bow Center was concerned with the environmental impact of their existing filtration system. There are 26 filtration units between the condenser water loop, glycol loop, cooling tower, primary chilled water loop, and primary heating loop of The Bow Center. Each uses filters that are not recyclable and the frequency of replacement meant significant and consistent waste. String filters are not recyclable or eligible for traditional landfill facilities.

- Upwards of 2700+ contaminated string filters were being replaced annually at a cost between $5.80 and $7.50 each.

- All 26 filters were being replaced twice weekly involving a full day of labour with each replacement.

- Disposal costs of $175 / ton with a $275 surcharge were also being incurred.

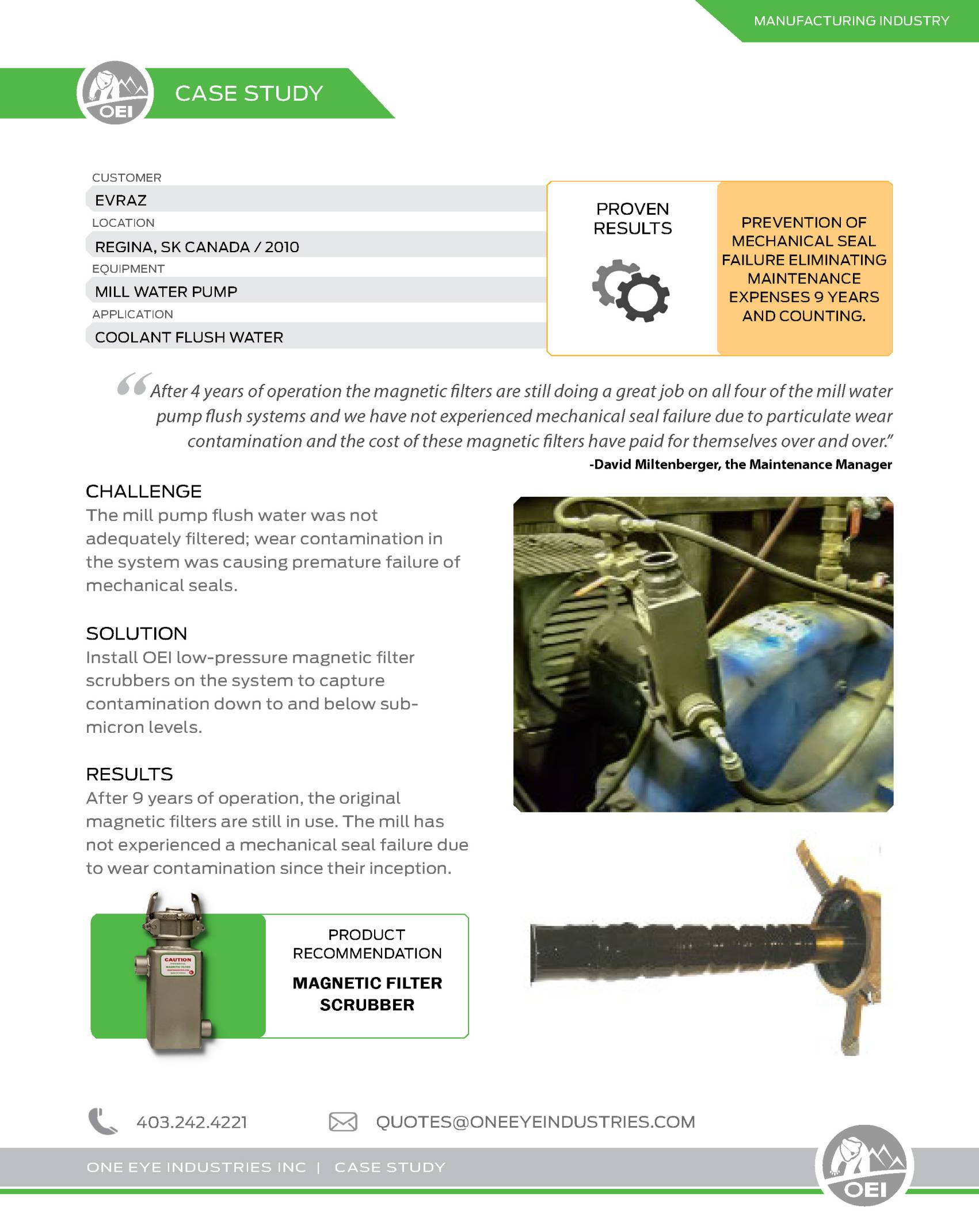

Evraz Coolant Flush Water Mechanical Seals

The mill pump flush water was not adequately filtered; wear contamination in the system was causing premature failure of mechanical seals.

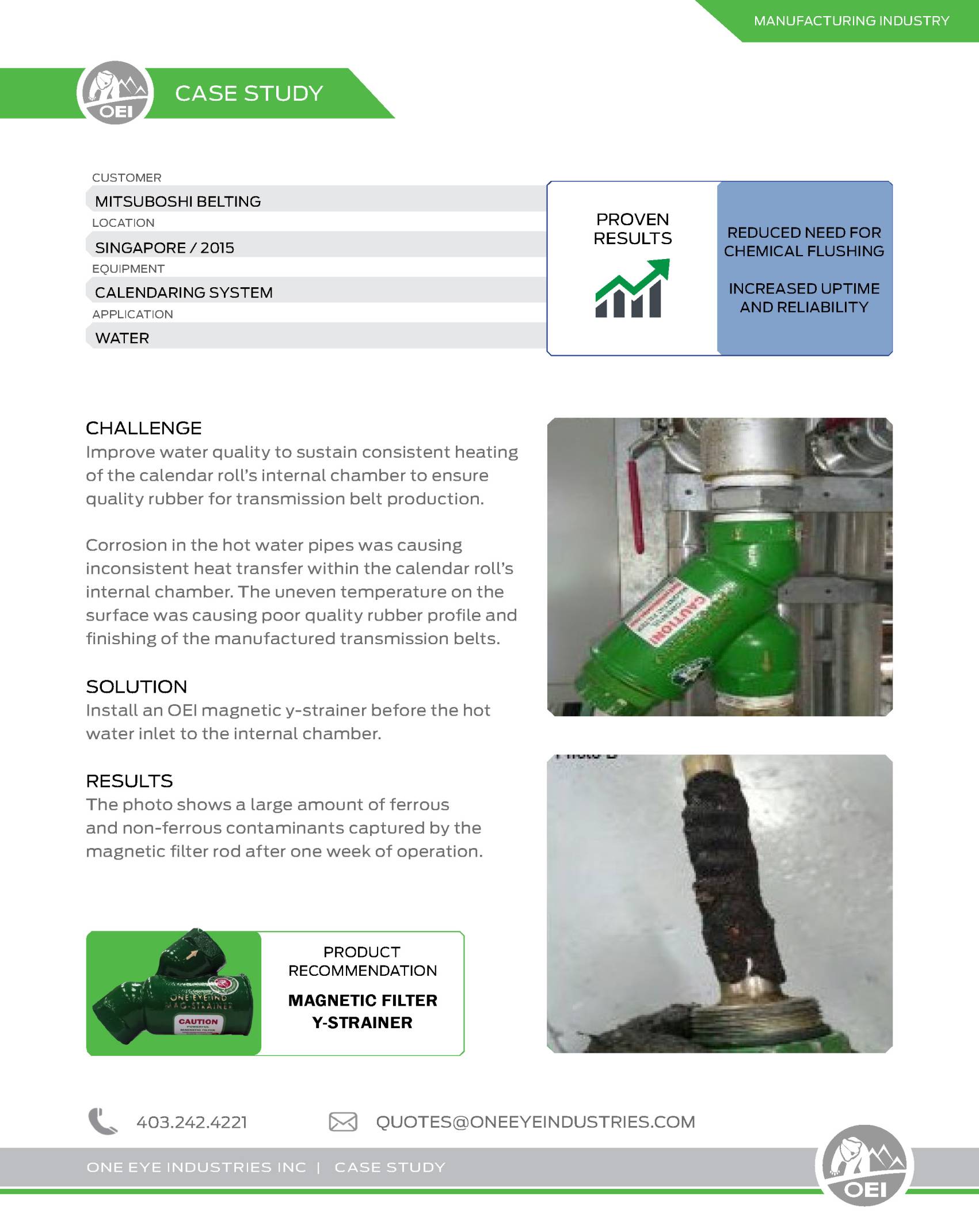

Mitsuboshi Belting Calendaring Hot Water System

The challenge was to improve water quality to sustain consistent heating of the calendar roll’s internal chamber to ensure quality rubber for transmission belt production.

Corrosion in the hot water pipes was causing inconsistent heat transfer within the calendar roll’s internal chamber. The uneven temperature on the surface was causing poor quality rubber profile and finishing of the manufactured transmission belts.

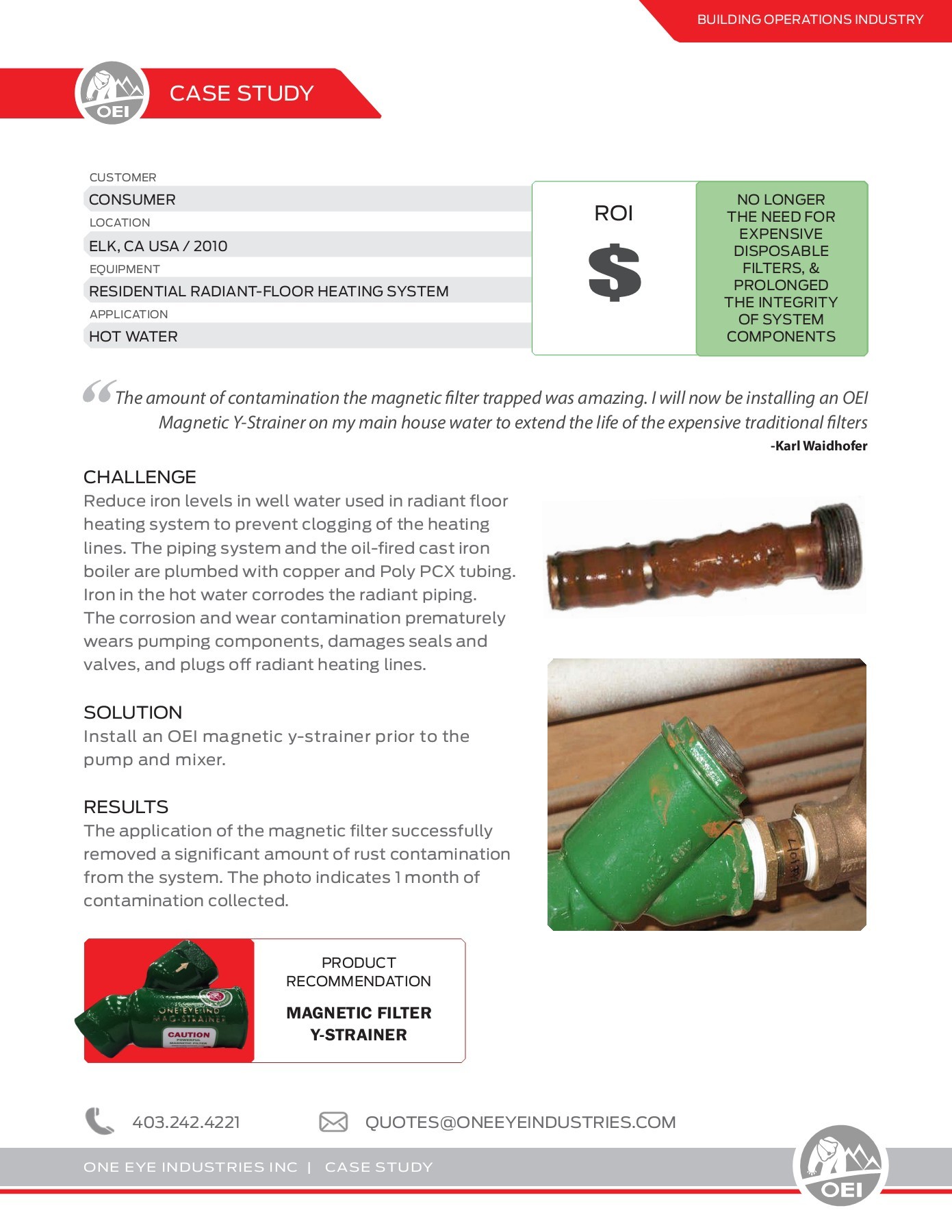

Radiant Floor Heating System Reliability

The challenge was to reduce iron levels in well water used in radiant floor heating system to prevent clogging of the heating lines. The piping system and the oil-fired cast iron boiler are plumbed with copper and Poly PCX tubing. Iron in the hot water corrodes the radiant piping. The corrosion and wear contamination prematurely wears pumping components, damages seals and valves, and plugs off radiant heating lines.

OEI magnetic filters are designed for 95+% efficiency: they are optimized for fluid viscosity, flow volume, flow rate, temperature, mobility, and mounting requirements.

Use of the OEI Data Form will provide the necessary specifications for OEI to determine which product is right for you

REQUEST A QUOTE

4344 12th Street SE Calgary,

AB T2G 3H9 Canada

(403) 242 4221

quotes@oneeyeindustries.com