I was impressed by the amount of wear contamination under 4 microns that was removed by the magnetic filter element

Challenge

Evaluate the efficiency of the airframe and transmission mounted mechanical filters for a Bell Medium main rotor transmission test run stand. Identify the size and quantity of wear contamination under 4 microns in size in the oil that causes the majority of premature wear of components like bearings.

Wafer Filter

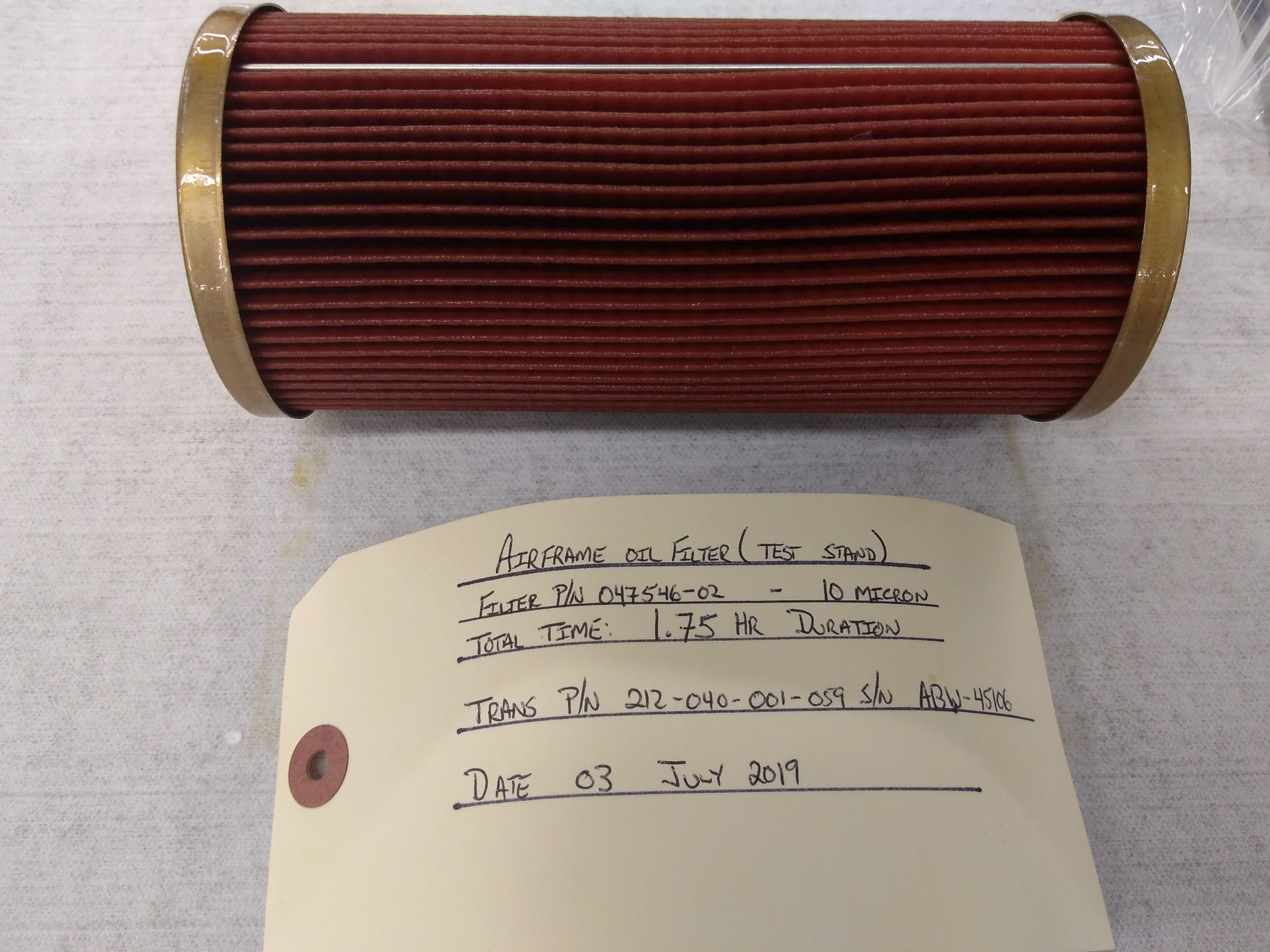

Air Frame Filter

Solution

Install an OEI magnetic filter downstream of the airframe paper filter element (10 micron) and wafer filter (80 micron. Identify wear contamination particle sizes and quantities present in the oil after 1 hour of run time.

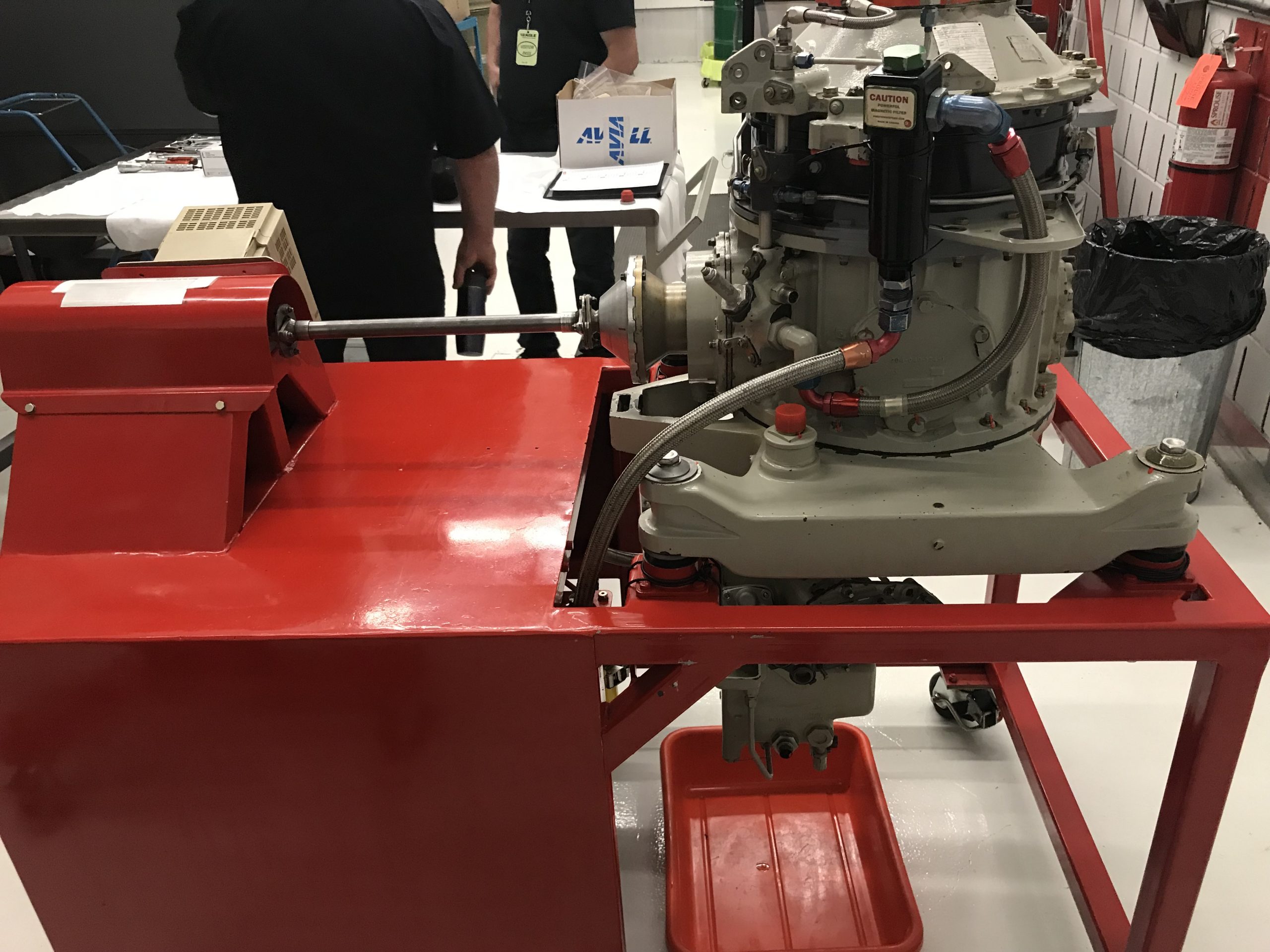

Transmission Run Stand With OEI Inline Magnetic Filter Scrubber

Results

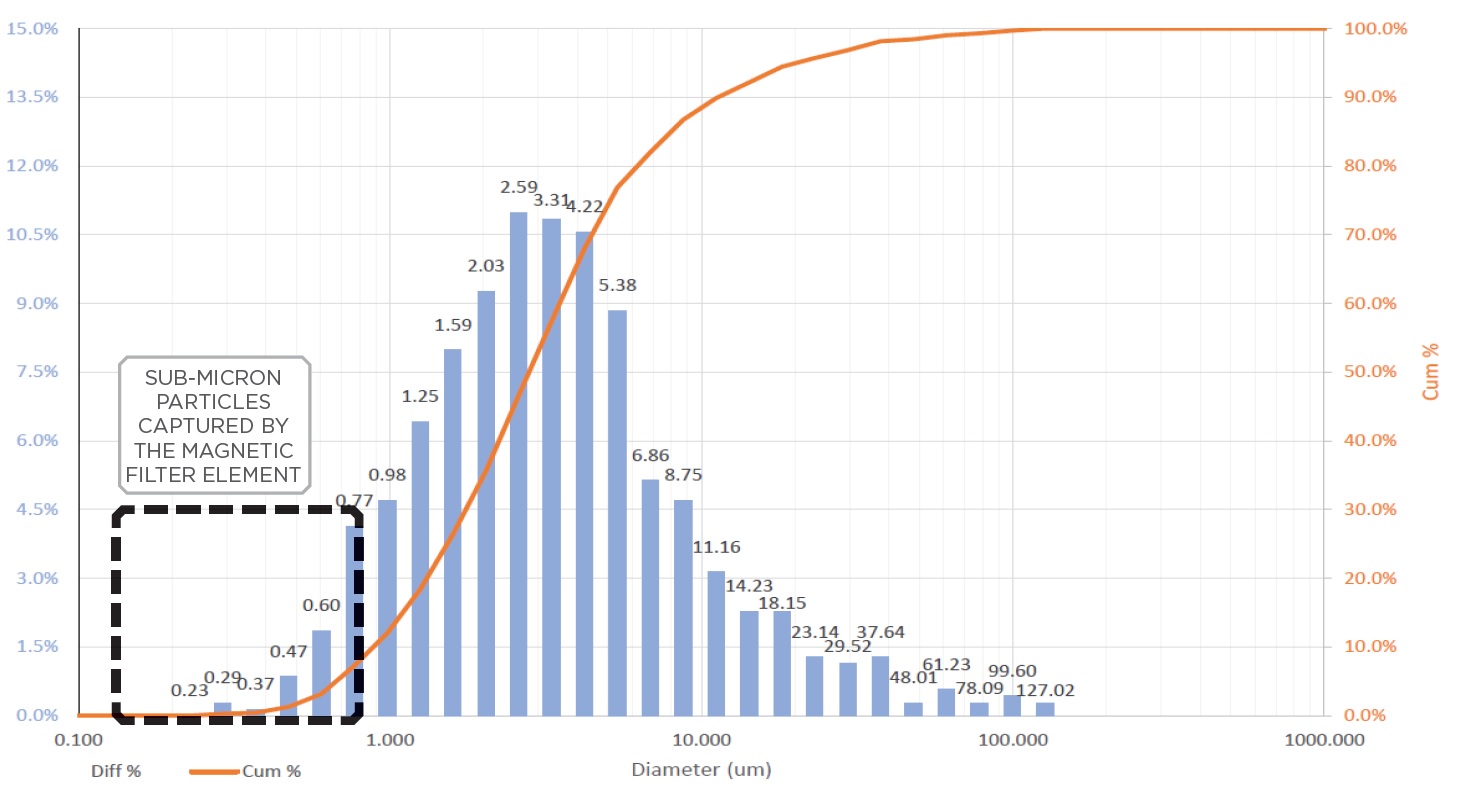

The SEM/PSD and XRD/EDC contamination analysis identified 66% of the wear particles were under 4 microns with 13% of that under 1 micron. The remaining 21% of wear particles ranged up to 127 microns in size.

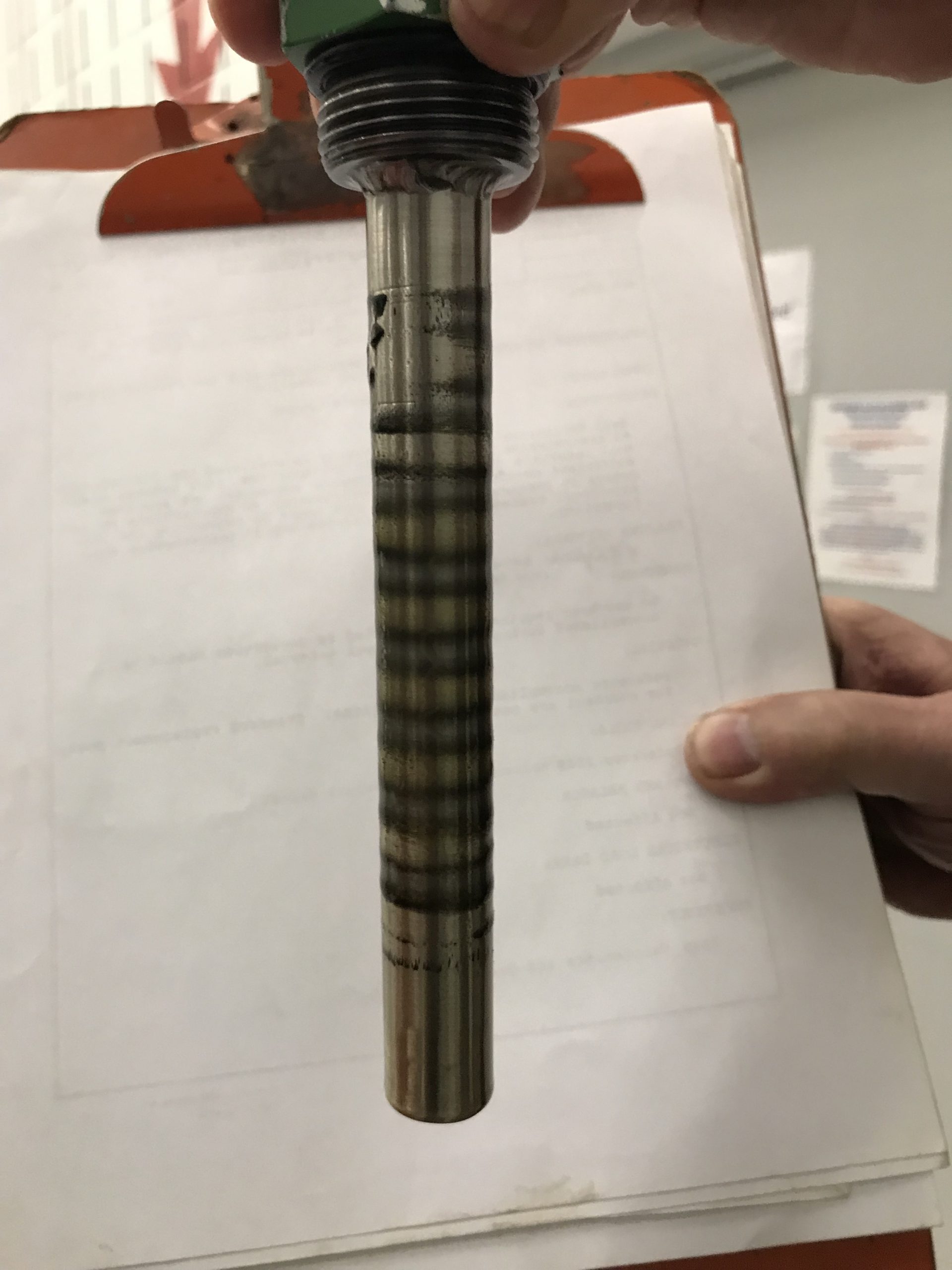

Contamination Captured After 1 Hour Of Runtime

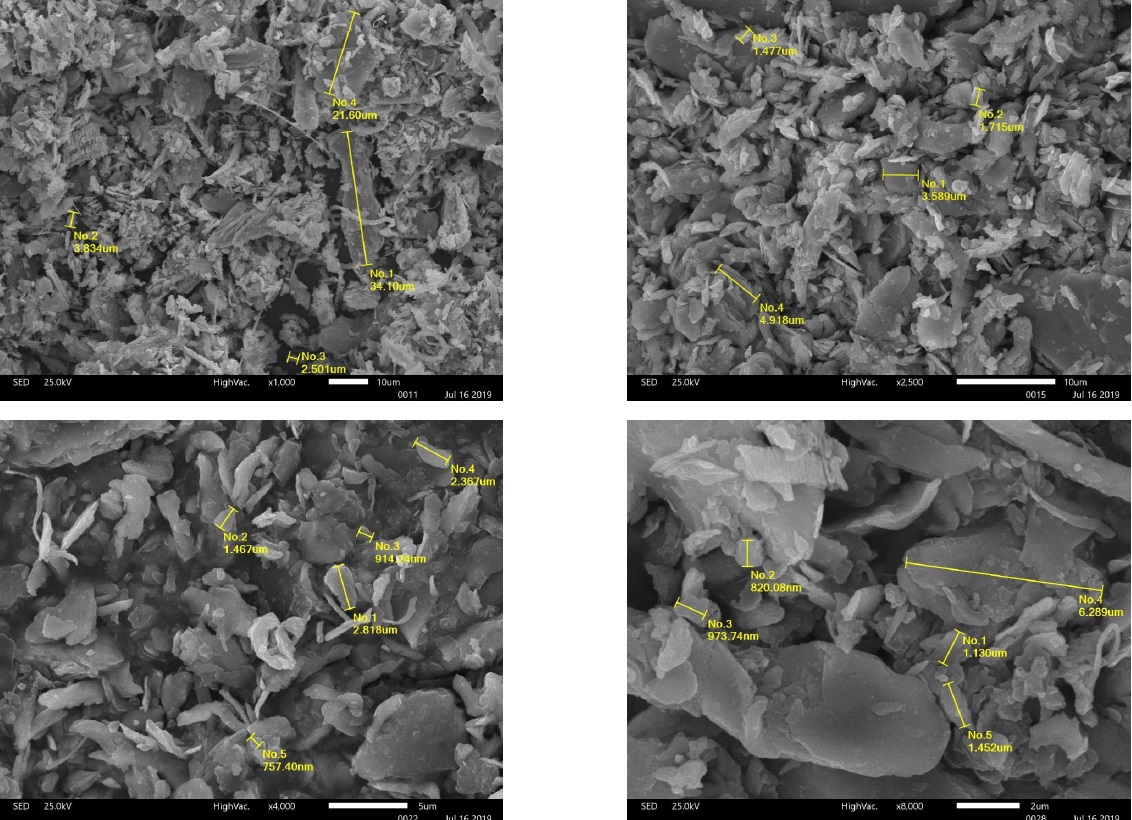

SEM / PSD ANALYSIS

» SEM was used to observe and count the particles in the sample to obtain the particle size distribution. Size is measured by length in micrometers. Statistics and analysis is based on total counts measured by SEM. SEM was conducted on a JEOL – JSM300 LV.

» The results of SEM analysis showed that 13.1% of total particles were found to be under 1 micron and 65.9% of particles were found to be under 4 microns.

Contamination Sample Under Microscope

Particle Size Distribution From Solid Analysis

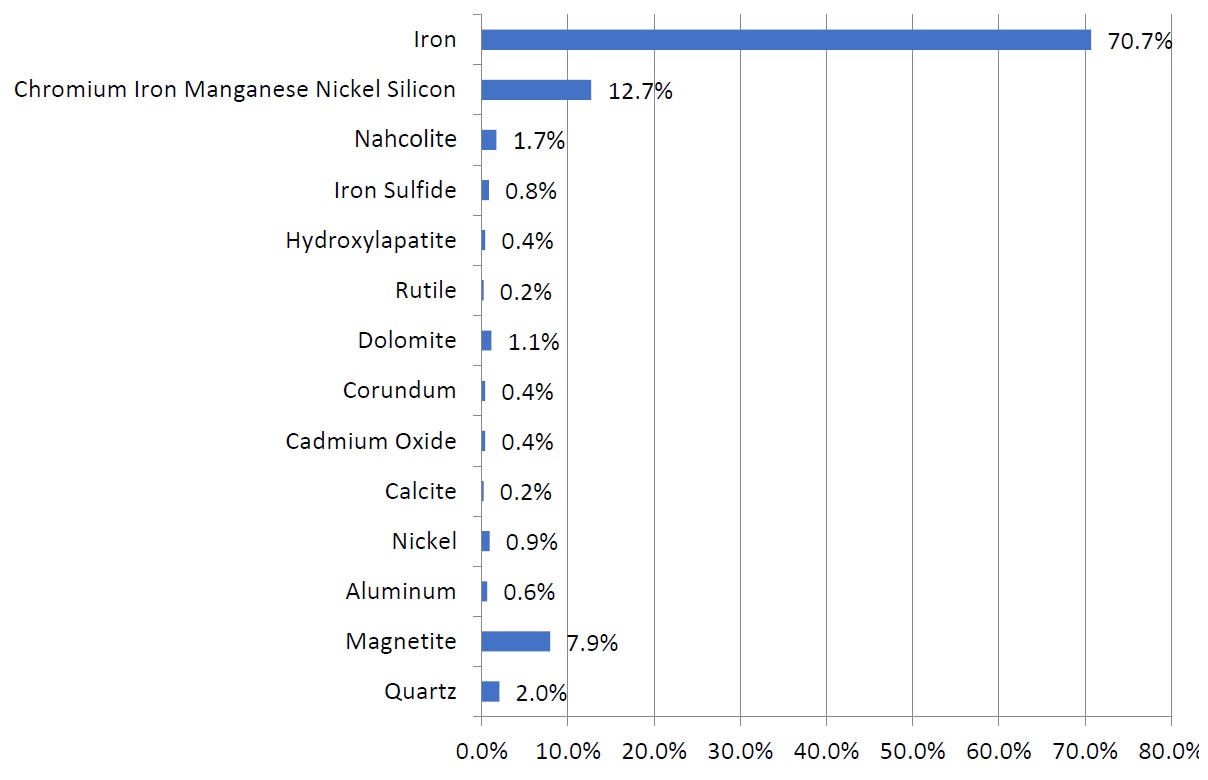

XRD / EDS ANALYSIS

» One of the magnetic filter samples received by SEMx Incorporated was analyzed using X-ray diffraction

(XRD) and energy-dispersive X-ray spectroscopy (EDS).

» Solids were wiped off the filter and washed by solvent prior XRD EDS PSD analysis.

The sample was finely crushed and ground using an Agate mortar and pestle in preparation for XRD

and EDS analysis. XRD was employed to identify and quantify the phases present in the sample.

» XRD data was collected using a PANalytical Aeris X-ray diffractometer. Qualitative XRD analysis and

Rietveld Refinement was performed using HighScore Plus XRD analysis software.

EDS was used to determine the elemental composition of the sample and helped to verify the results

obtained with XRD quantification. EDS was conducted using a JEOL JED-2300 DRY SDD EDS detector.

» This analysis quantifies the amount of both ferrous and non-ferrous wear contamination caught by

OEI magnetic filter elements. Ferrous contamination presented at more than 78.6%, while non-ferrous

contaminants, such as Chromium, Dolomite, Manganese and others totalled approximately 21.4%.

XRD Weight Percentages

SEM ANALYSIS

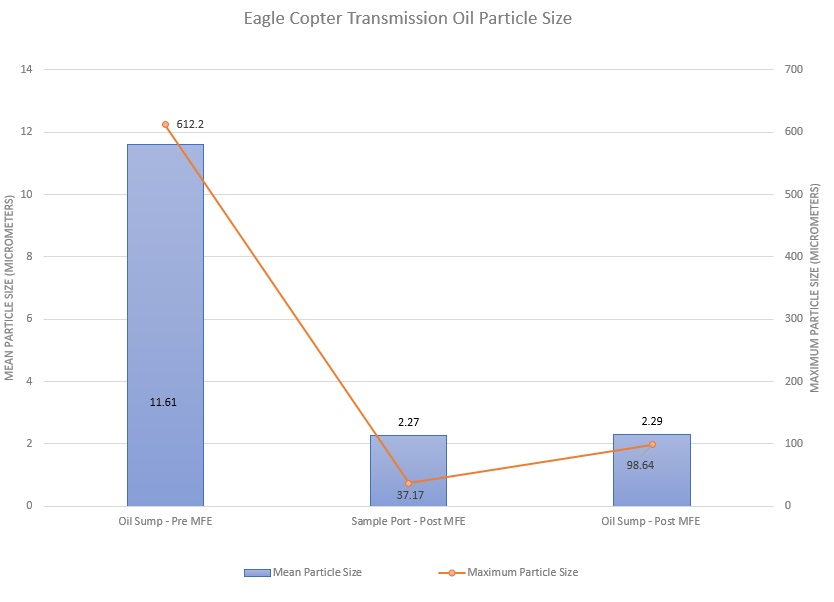

» The results of SEM analysis showed that the maximum particle size decreased over 83%, after using

the OEI magnetic filter. The mean particle size declined approximately 80% with mean particles size

decreasing from 11.6 to 2.3 microns.

Oil Sample Comparisons